When light meets water, magic happens

Pushing the limits of material processing with Laser MicroJet® Technology

Who we are

Our mission is to help manufacturers increase productivity and gain a technological advantage by providing cutting-edge and precise material processing solutions.

With Synova’s water jet guided Laser MicroJet technology, we empower businesses worldwide to expand their processing capabilities, reduce costs, and achieve superior cutting quality, even when working with the most complex materials.

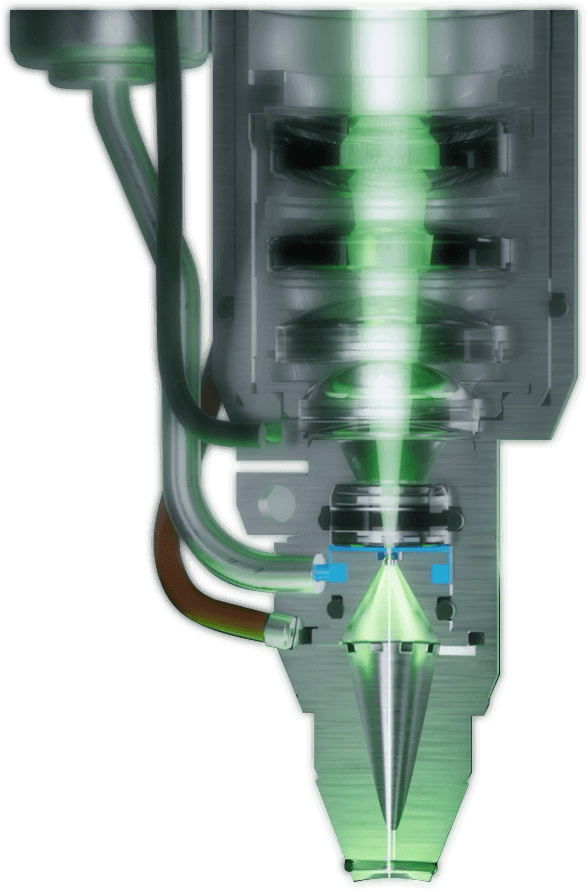

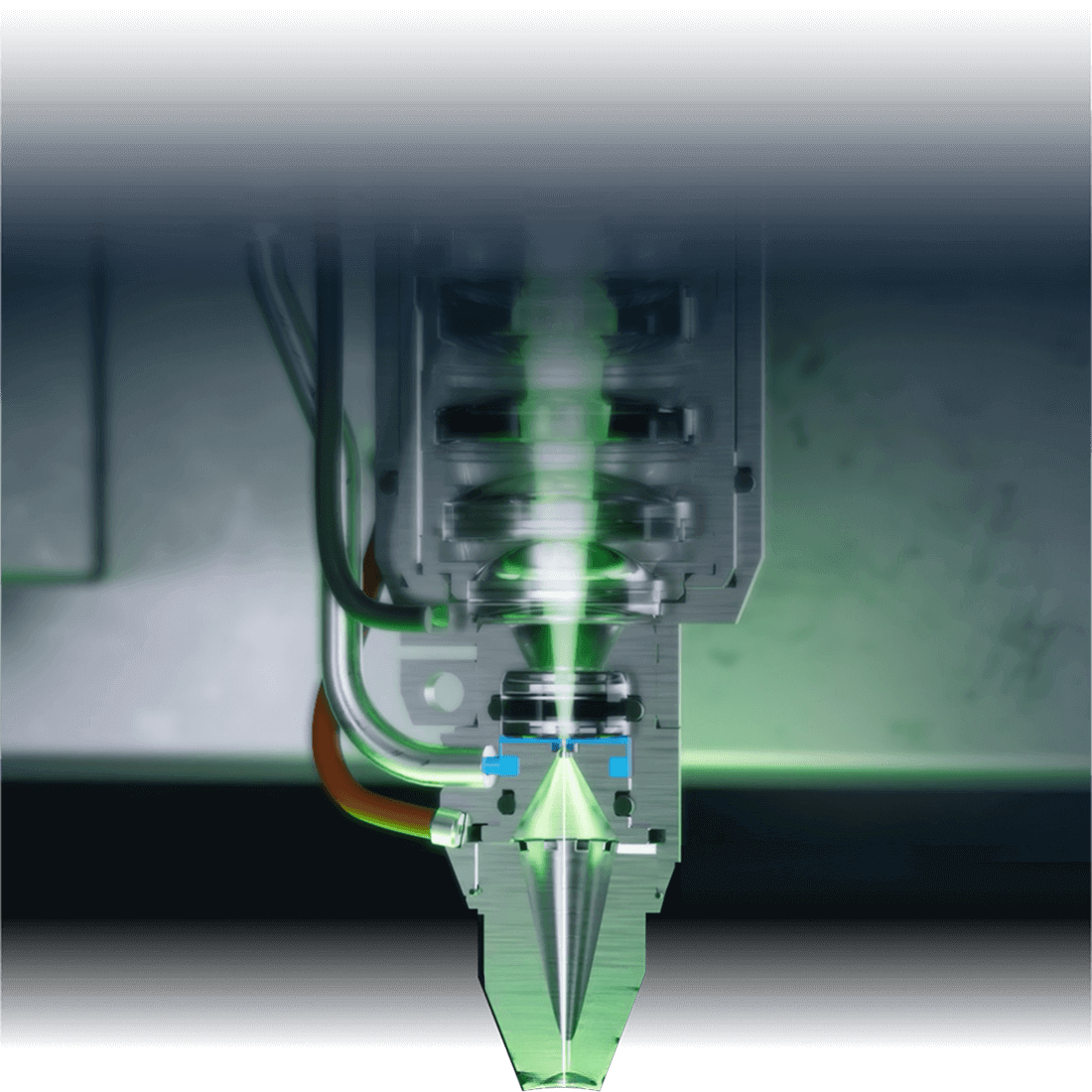

How it works

A Revolutionary Precision Solution

Laser MicroJet (LMJ) technology uniquely combines a green laser with a hair-thin water jet that precisely guides the laser beam through total internal reflection. This unique, water jet guided laser technology ensures smooth, clean and precise material processing.

Play video

High quality and precision

The workpiece is machined with high mechanical precision, low surface roughness, without micro-cracks and structural changes.

No heat damage

The water effectively reduces heat generation and ensures a clean cutting surface, free of deposits and burrs.

Parallel cut walls

The cylindrical laser beam produces tight, parallel kerfs (>30 µm) without taper.

News and Events

Stay updated with Synova

What we do

Industries we serve

Semiconductor, Aerospace, Medical, Diamond: Discover how Synova’s innovative Laser MicroJet technology and customized solutions empower industries, delivering precision, efficiency and value every day.

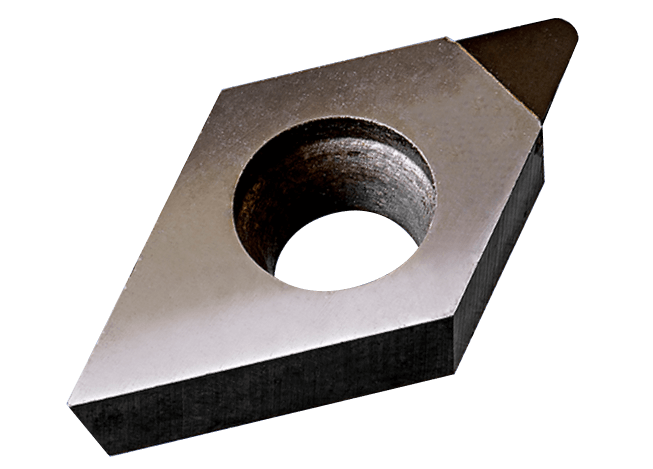

Semiconductor

Wafer and Equipment Processing

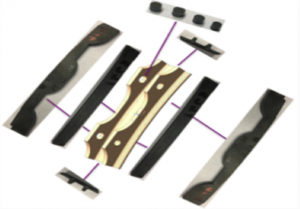

Diamonds

From Brilliant to Fancy Shapes

Aerospace

Advanced Precision for Jet Engines

Medical

Cutting-Edge Solutions for Medical Devices

Others

Ideal for various precision machining applications

Case studies

Synova’s Laser Solutions

Our Laser MicroJet solutions

Explore our range of machines and find your ideal LMJ system to optimize your manufacturing processes.

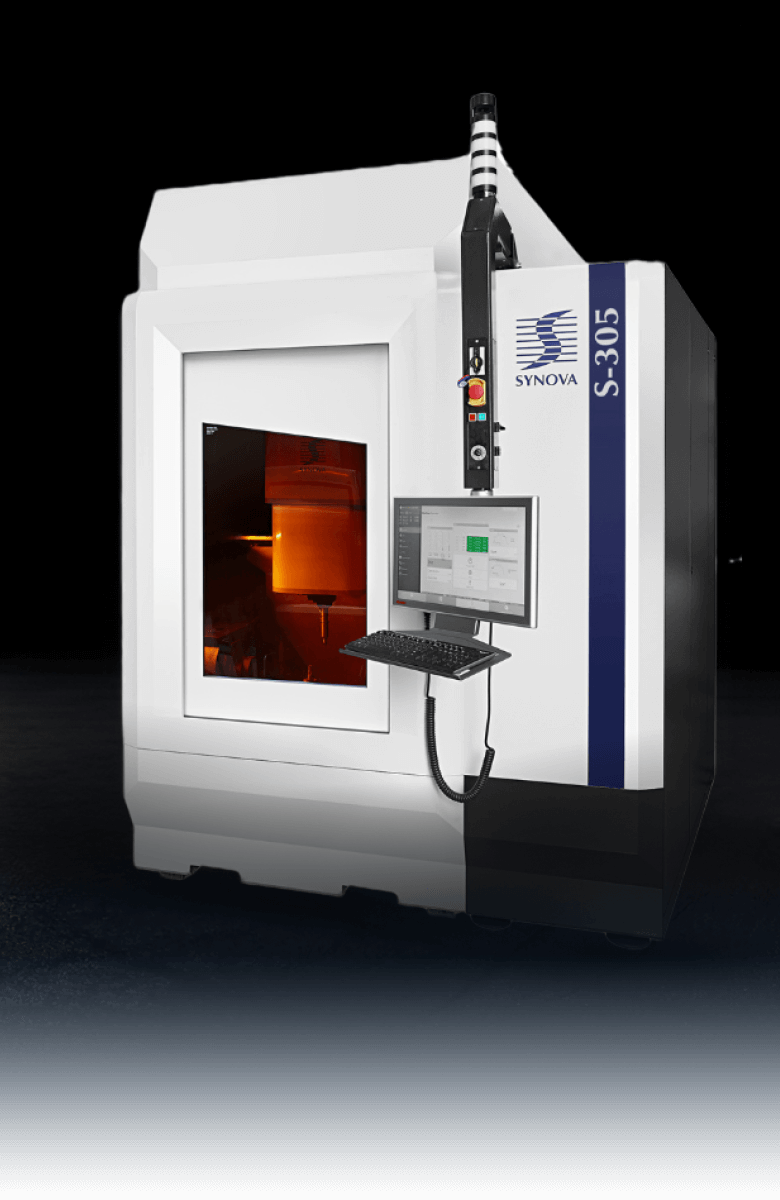

LMJ Systems

All machines are powered by the unique water jet guided laser technology. From compact solutions to high-performance laser machining centers, find the perfect solution for your application.

Integration Package

The LMJ-iP kit offers the flexibility to integrate the core components of our technology into existing production systems.

Synova’s services

Your partner for jobshop services and customer support

Whether you need feasibility testing, on-demand jobshop services, or dedicated support to optimize your operations, our team is ready to assist. From prototyping to full-scale production, specialized training, and technical support, we make sure you get the most out of our Laser MicroJet® technology.

Leading companies worldwide trust Synova’s Laser MicroJet® technology for their manufacturing processes.

Are you interested in a demo?

Fill out the form and we’ll get back to you as soon as possible.