Aerospace

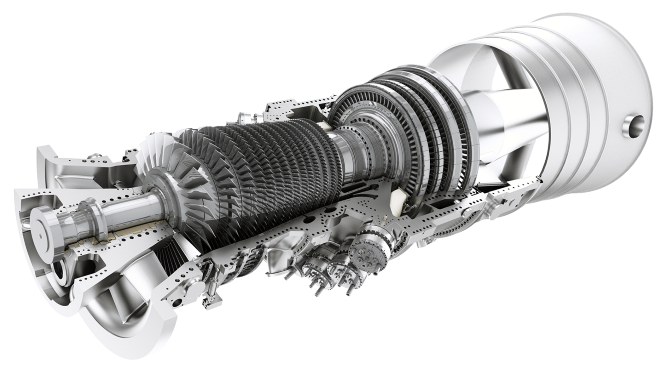

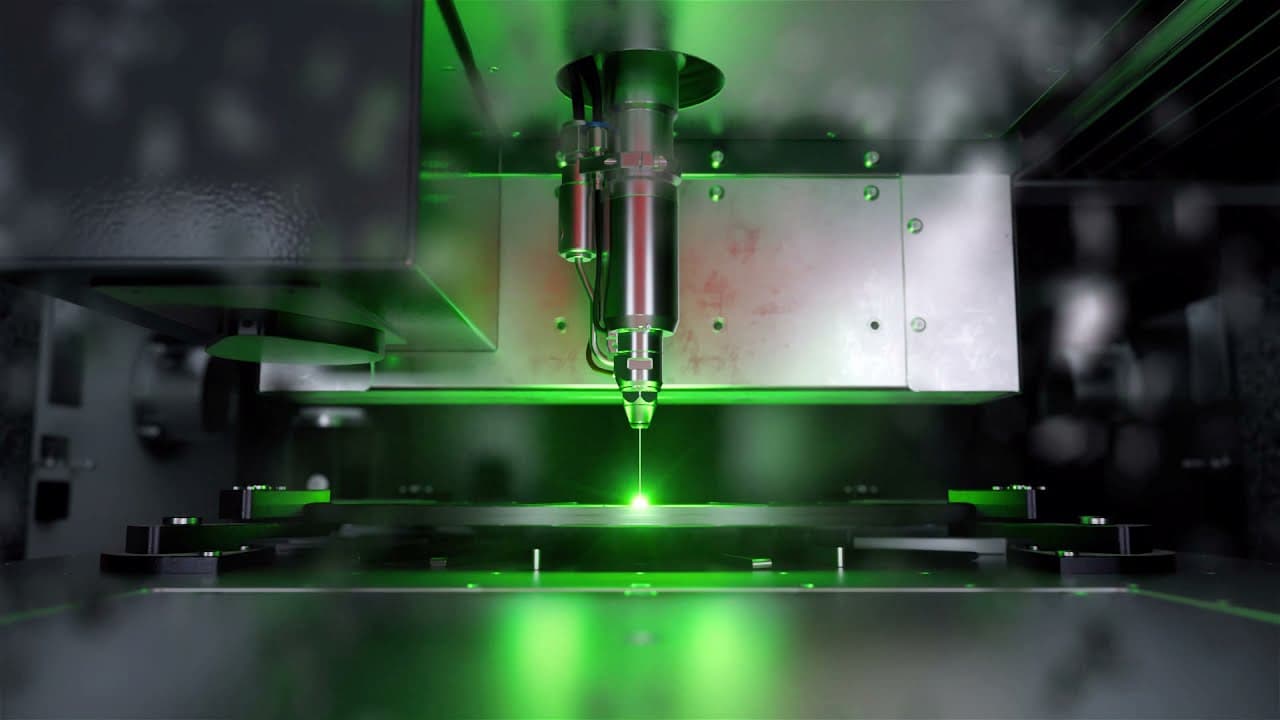

Synova’s advanced Laser MicroJet (LMJ) systems with 3 or 5 axes are perfectly suited for machining high-precision parts in the energy and aviation industry.

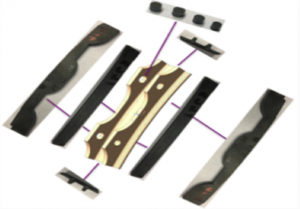

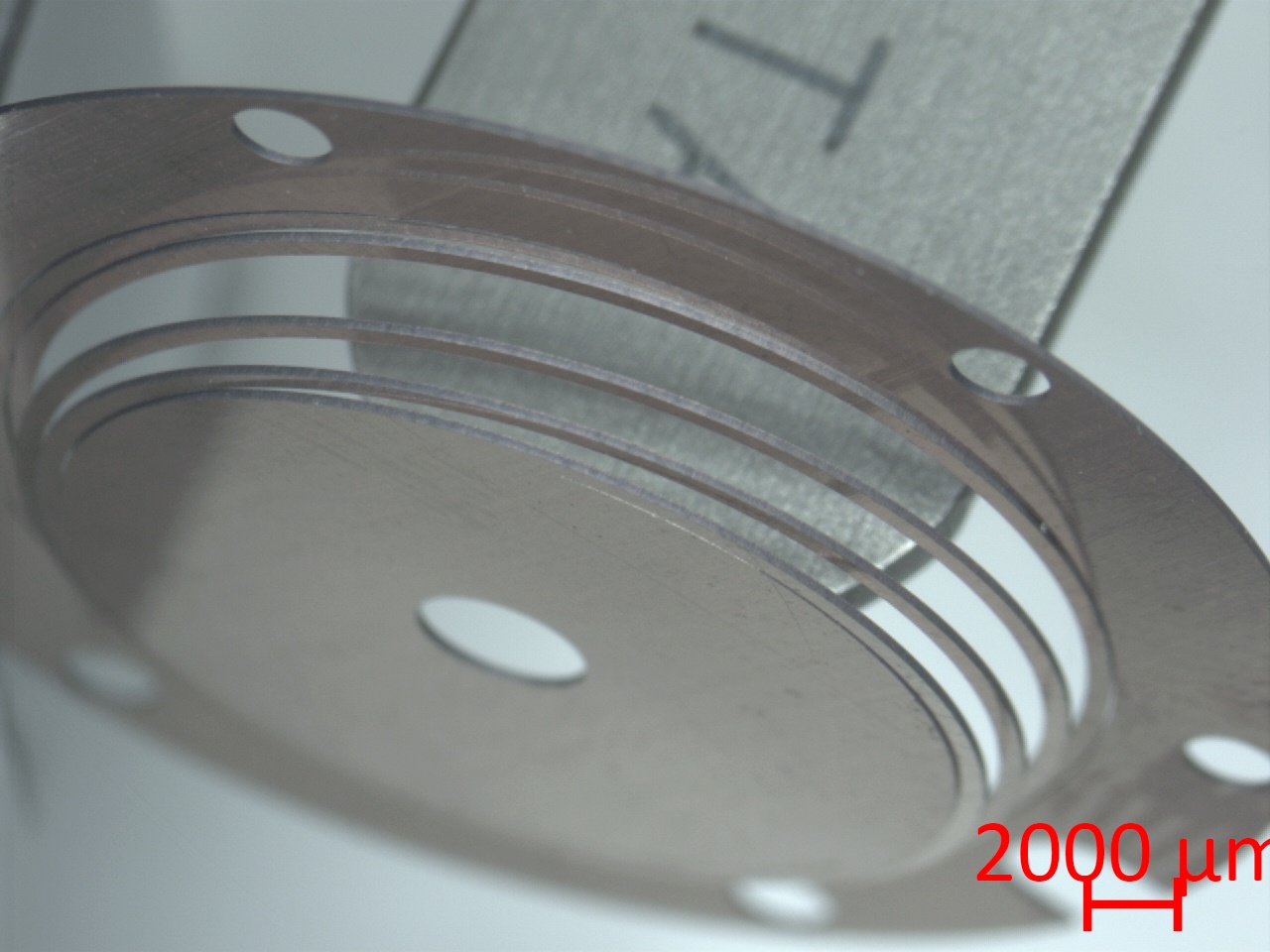

The hybrid water jet laser method provides precise through-hole drilling in hot section components of industrial gas turbines for cooling that require special materials such as thermal barrier coatings. Superalloys with or without thermal barrier coating can be processed in one simple step, without cracks or delamination in the ceramic coating and extremely low recast in the metal structure.

The LMJ systems are able to drill round and shaped holes (square, trapezoidal and inclined) at high process speed and with excellent quality at the entry and exit of the hole as well as on the sidewall.

Compared with conventional laser methods, the technology’s “wet” approach offers a less aggressive cutting process without causing heat damage. The water jet continually cools the cutting zone and efficiently expels contaminants from the work piece surface. Any kind of metal, hard material and most ceramic-matrix composites, for example zirconia, alumina or silicon carbide can be machined. The running costs of the LMJ systems are low since there is no tool wear, very few consumables and low waste rates.

Despite the limited time I could get a first in-depth insight into the LMJ potential for ablating TBC and superalloy materials. We could also identify first promising process windows for ablation at high removal rates, particularly for metals, with quality still likely to meet our typical production requirements.

The LMJ process has a particular strength in the processing of superalloy metal material. Here the benefit from the local cooling by the water jet and the tolerant focus position are real assets, allowing to realize high removal rates at good quality.

Alstom (now GE) after first LMJ machining tests

Materials

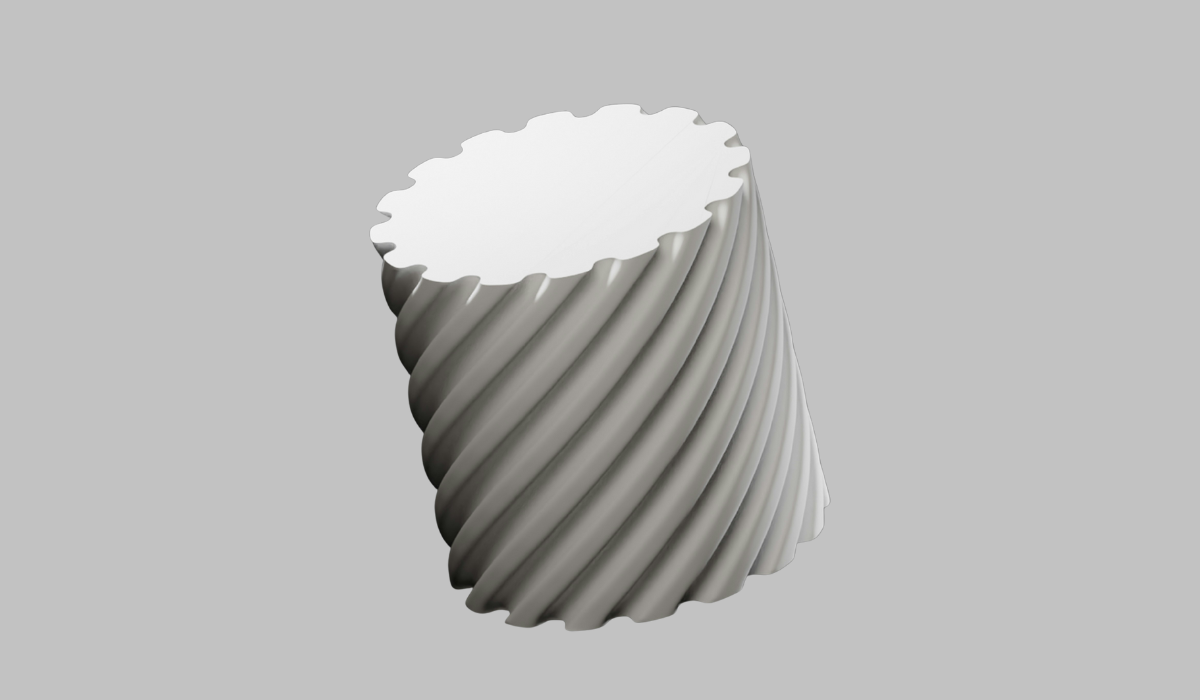

Our Laser MicroJet technology offers great results for the machining of a wide range of materials, whether conductive or not. It is particularly well suited for the processing of ultra-hard materials, such as super alloys, or of complex materials, such as CMCs.

Metals and alloys

Stainless steel, aluminium, Durnico, Phynox, CuBe, copper, brass, gold, shape-memory alloys (nitinol, cobalt-chrome), titanium, nickel, superalloys

Ceramics

Zirconia (ZrO2), HTCC/LTCC, aluminium nitride (AlN), alumina (Al2O3), silicon nitride (SiN), Polycrystalline cBN (PcBN), tungsten carbide (WC)

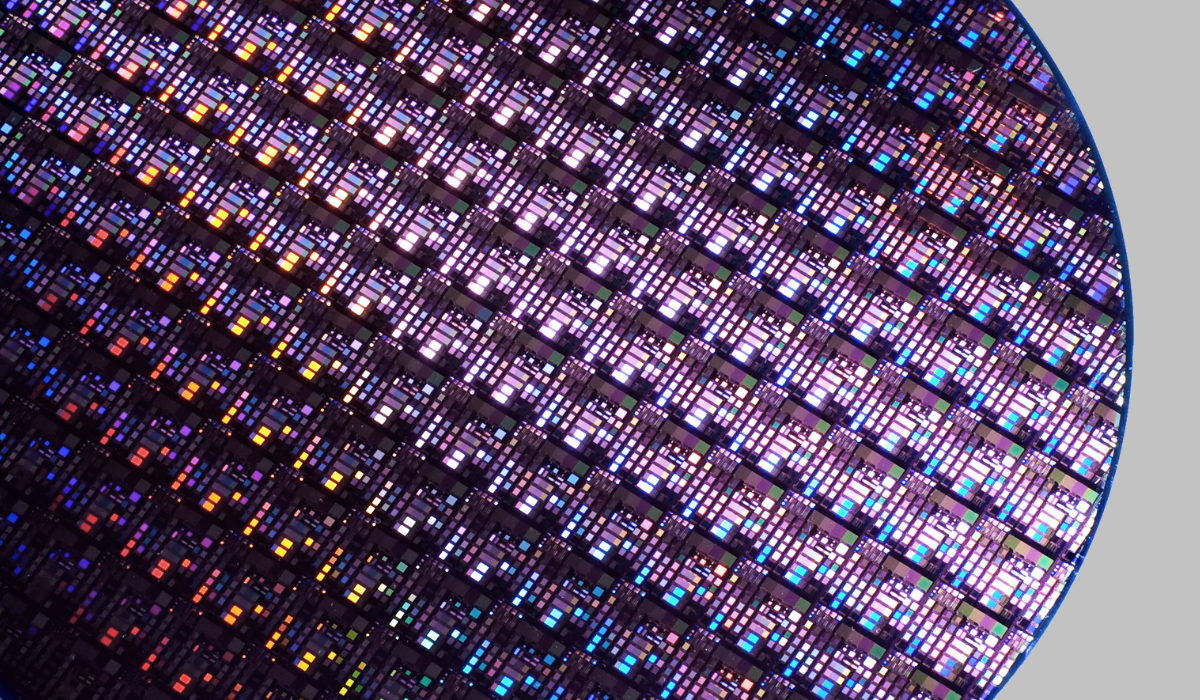

Semiconductors

Silicon (Si), gallium arsenide (GaAs), silicon carbide (SiC)

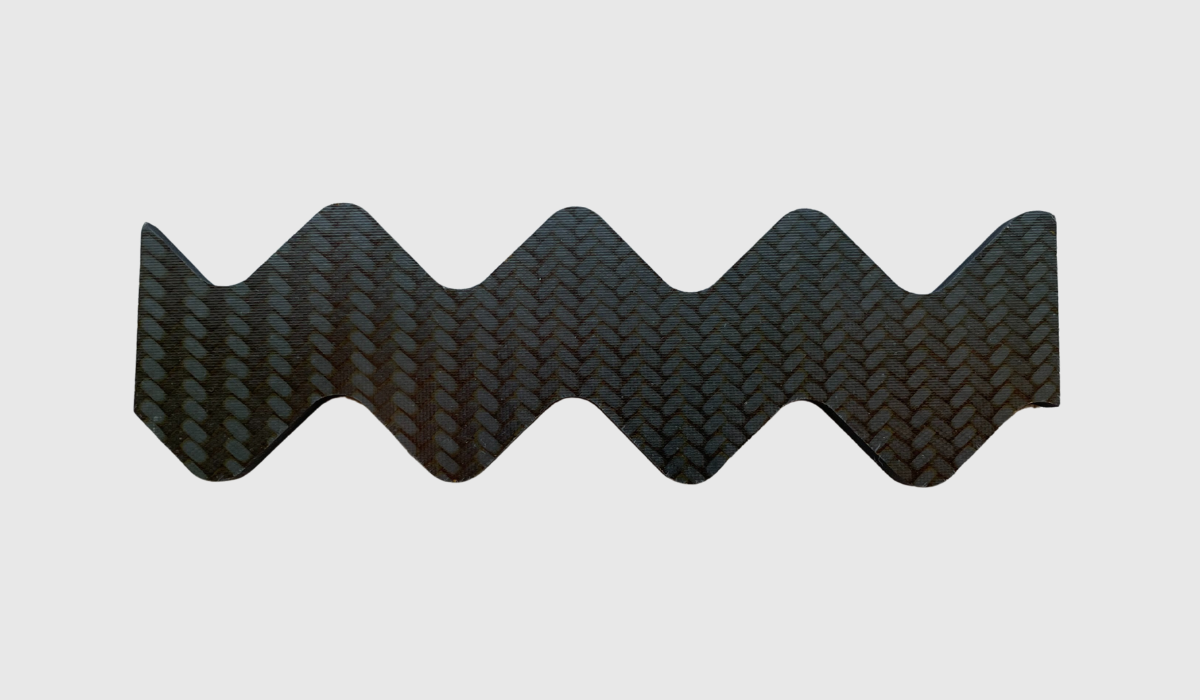

Composites

Ceramic matrix composites (CMCs), diamond-SiC/cBN composites, carbon fiber reinforced polymer (CFRP)

Application Examples

Diffusor holes

Coated superalloy

Diffusor holes

CMC

Aerospace structure

CFRP

Component

Beryllium copper

Component

Silicon carbide

Case studies

Olivier Lafon

(Business Unit Manager – Aerospace)

Meet our Business Unit Expert

Our business expert is here to support you every step of the way, whether you’re considering an application test, exploring our job shop services, or looking to discuss your upcoming production needs.