Jewellery Diamonds

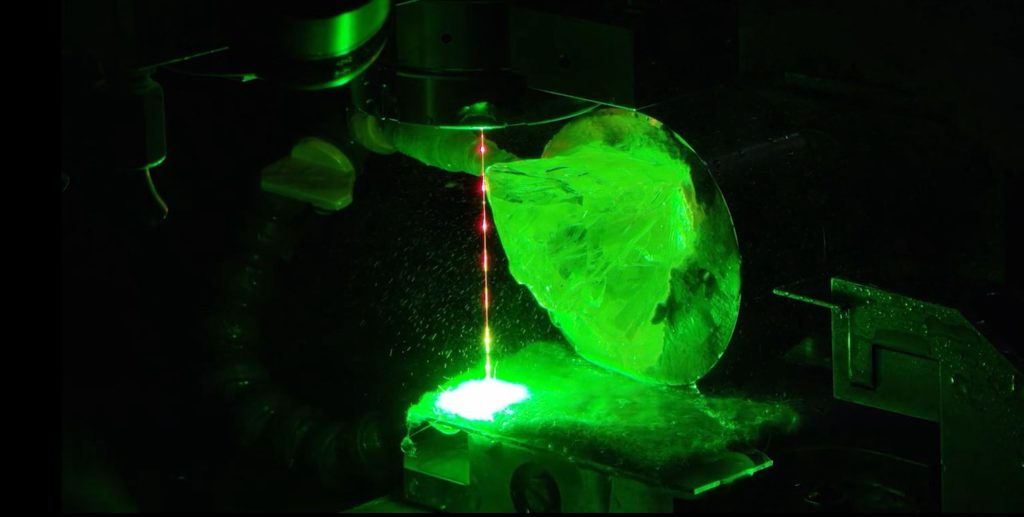

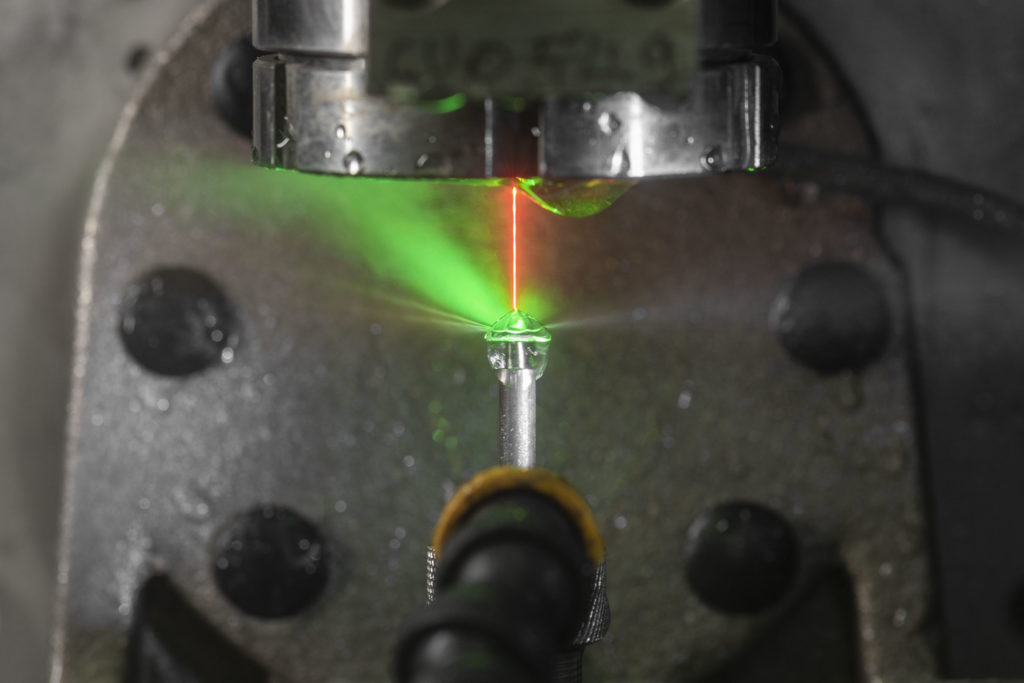

With over 15 years of expertise in laser cutting for the diamond sector, Synova has pioneered the development of Laser MicroJet® cutting systems tailored specifically for diamond manufacturers. Our technology combines a powerful laser beam within an ultra-fine water jet, enabling unmatched accuracy, minimal weight loss, and superior surface quality.

Synova’s solutions are engineered to meet the highest standards of the diamond industry with minimal risk of breakage, even in high-tension stones. From pie and curve cutting to round brilliant faceting and fancy shapes cutting, our systems offer unparalleled flexibility and efficiency. With easy integration into blockchain and traceability systems, Synova’s machines are not only future-ready but also simplify and accelerate the entire Midstream sector.

Explore below how our machines are transforming diamond manufacturing through real-world applications, and discover success stories from industry leaders who trust Synova’s technology to elevate their production.

Practical Applications of Laser MicroJet® in Diamond Manufacturing

Round brilliant faceting

Fancy shapes cutting

Laser sawing

Pie cutting

Hole drilling

Revolutionizing the Diamond cutting journey with the Laser MicroJet®

1

Rough stone

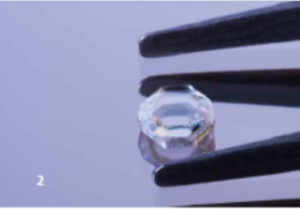

2

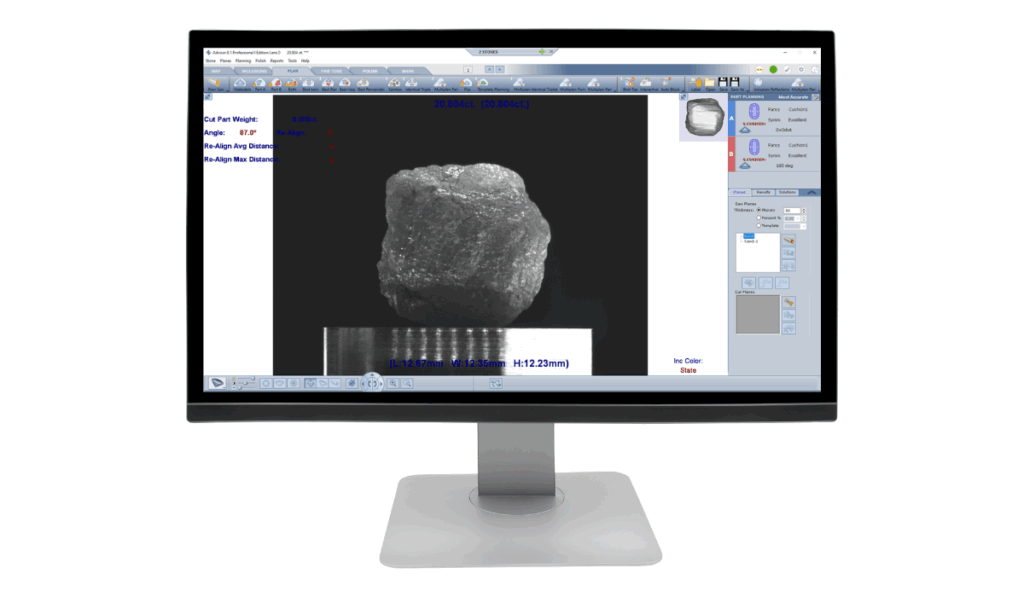

Scanning

3

Planning

4

Sawing

5

Blocking & Faceting

6

Final polishing

7

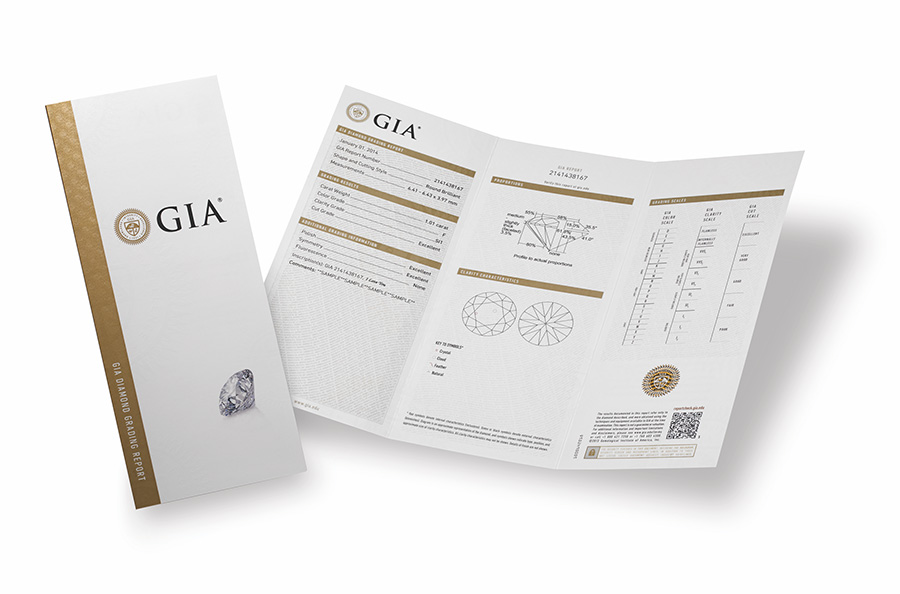

Grading

8

Ready for retail

Laser sawing with DCS machine

Synova’s Laser MicroJet® technology offers an ideal solution for diamond sawing. Designed for rough stones starting from over 3 carats and proven on diamonds weighing up to 1,100 carats, the system enables accurate sawing or pie cutting with minimal material losses.

The rough stone is securely mounted on a Diamond Orientation Platform (DOP), ensuring optimal alignment for precise cuts. By combining a laser beam with a thin water jet, the Laser MicroJet® delivers parallel kerfs, smooth surfaces, and sharp edges, even when cutting through high-tension zones. This gentle approach significantly reduces the risk of breakage and preserve the value of each stone.

The system features a micrometer-precise machine, capable of executing complex geometries while delivering consistent and repeatable results. Fully autonomous and easy to operate, it requires only one technician with basic training. With its smooth cutting surfaces, sharp edges, and seamless integration into traceability systems, Synova’s solution sets a new benchmark in diamond processing.

Automatic faceting with the DaVinci machine

The DaVinci Diamond Factory® is Synova’s fully automated system that transforms rough diamonds into round brilliants, as well as fancy or custom shapes. It combines the entire cutting process, including sawing, blocking, bruting, and faceting into one compact solution. The DaVinci machine defines the optimal cutting sequence and automatically transitions from one facet to the next. Capable of producing up to 57 facets in a single operation, it requires only a minimal final polishing step.

Powered by Synova’s patented water jet guided laser technology, the DaVinci offers exceptional precision with thin parallel kerfs, while reducing diamond damage and weight loss. It also significantly reduces production time from several days to just a few hours (approximately 1 hour for 1ct polished stone). Additionally, the system enables the recovery and reuse of diamond cutting chips, maximizing yield and material efficiency.

Success stories

The Queen of Kalahari

|342 cts

The Constellation

|813 cts

Lasedi La Rona

|1109 cts

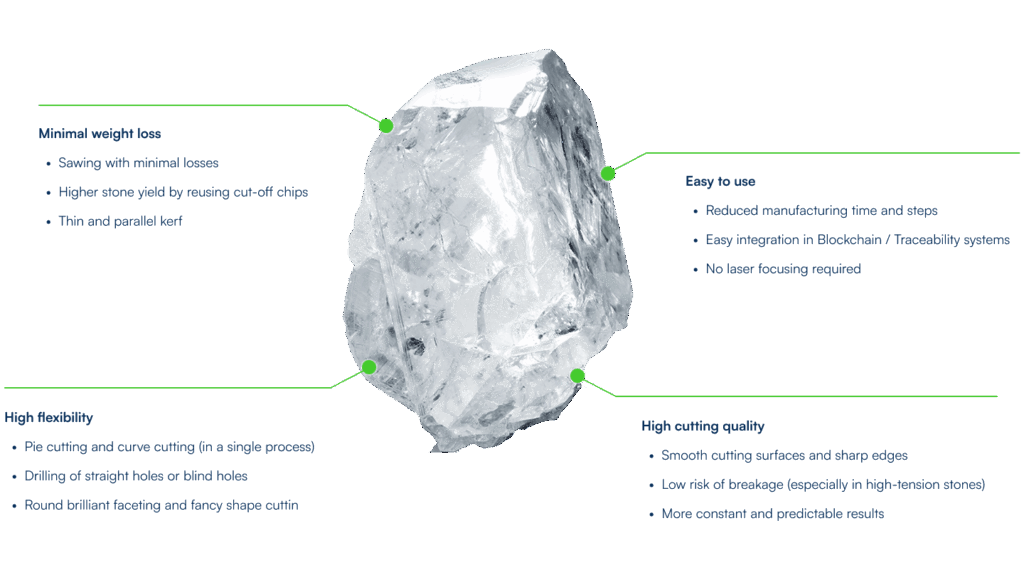

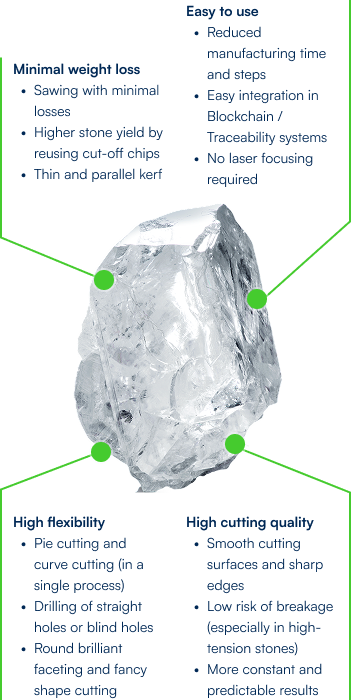

Advantages of the Laser MicroJet®

in the Jewelry Industry

Minimal weight loss

• Sawing with minimal losses

• Higher stone yield by reusing cut-off chips

• Thin and parallel kerf

High flexibility

• Pie cutting and curve cutting (in a single process)

• Drilling of straight holes or blind holes

• Round brilliant faceting and fancy shape cutting

Easy to use

• Reduced manufacturing time and steps

• Easy integration in Blockchain / Traceability systems

• No laser focusing required

High cutting quality

• Smooth cutting surfaces and sharp edges

• Low risk of breakage (especially in high-tension stones)

• More constant and predictable results

Industrial diamond

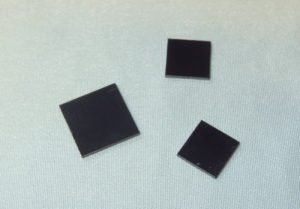

Synova offers cutting-edge solutions for processing both CVD and HPHT diamonds, leveraging its patented Laser MicroJet® technology to deliver unmatched precision and surface quality. From shaping intricate components for quantum sensors and optical devices to cutting industrial tools, Synova enables clean, heat-free, and highly accurate machining. Supporting innovation across high-tech industries, Synova is redefining diamond processing with sustainable, scalable, and locally adaptable manufacturing solutions.

Application examples

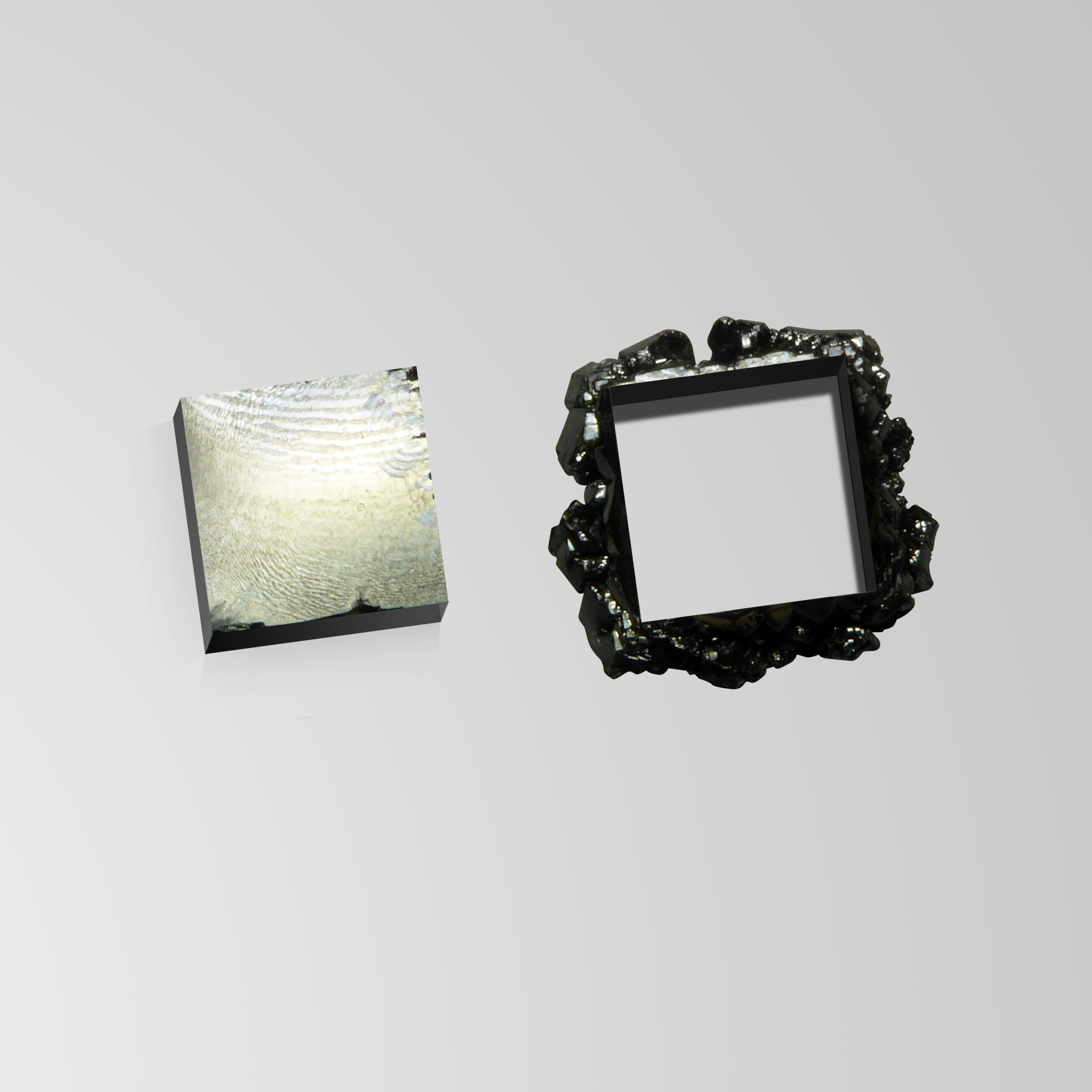

Coring (CVD diamond)

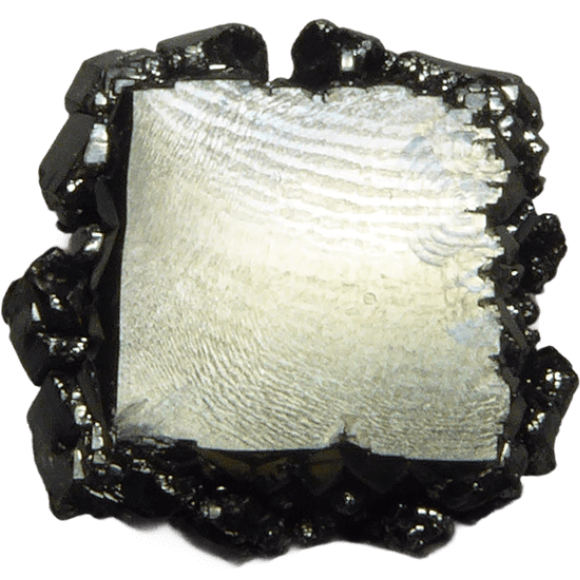

Slicing (CVD or HPHT)

Circular saw blade

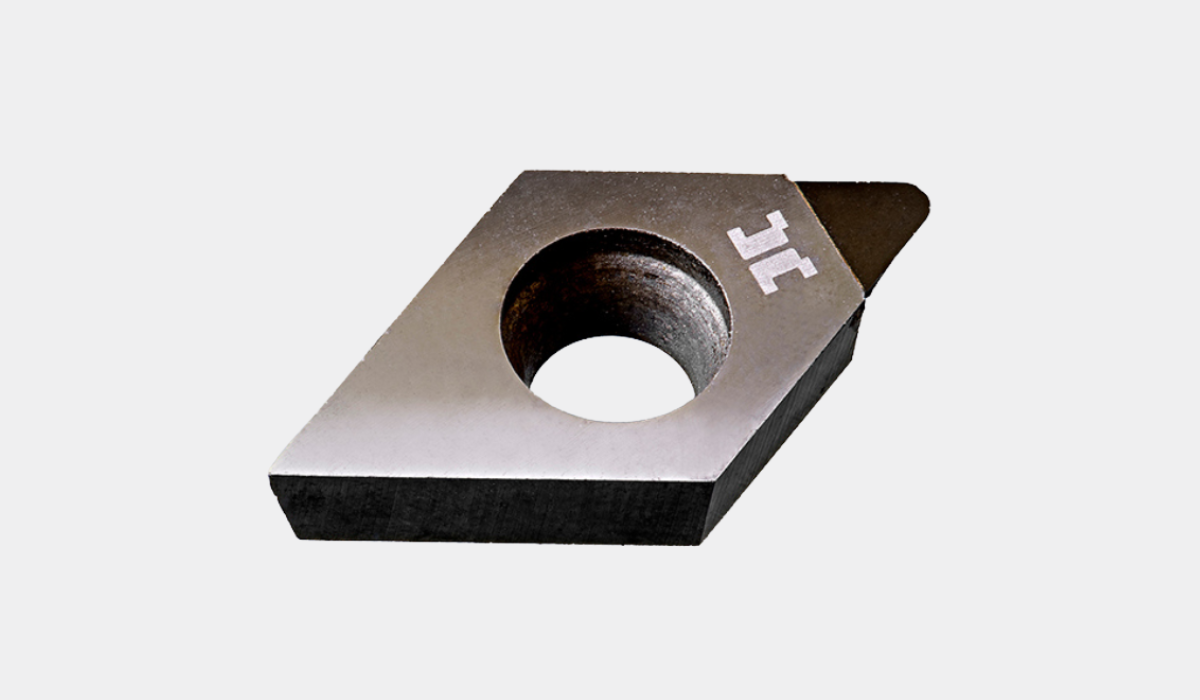

Tool insert

Quantum

Case studies

Advantages of the Laser MicroJet®

for industrial diamonds

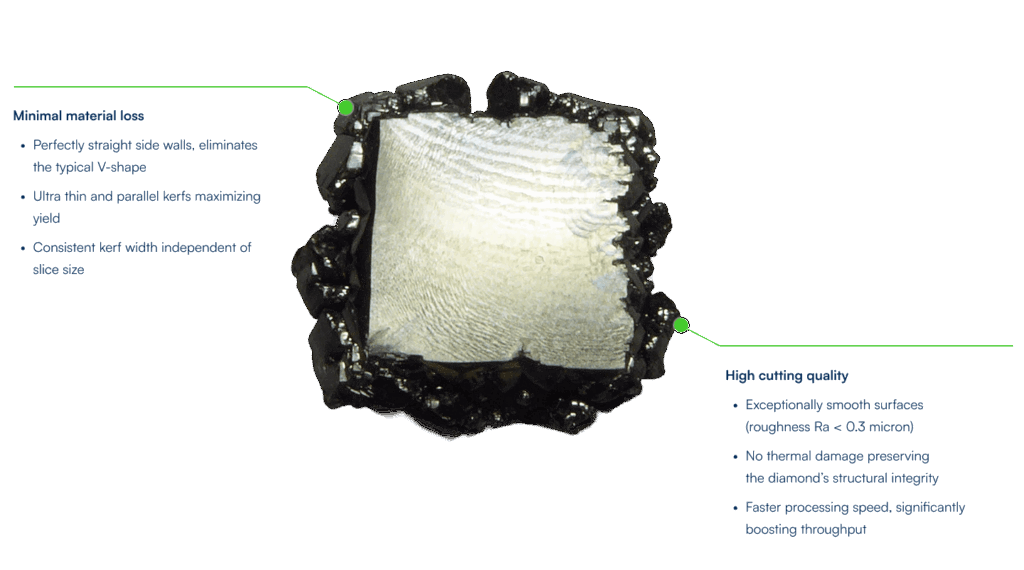

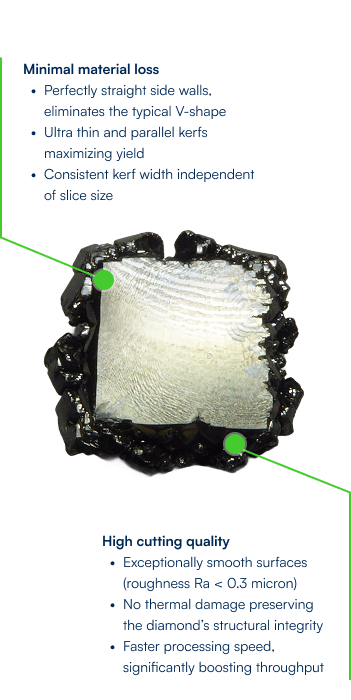

Minimal weight loss

• Perfectly straight side walls, eliminates the typical V-shape

• Ultra thin and parallel kerfs maximizing yield

• Consistent kerf width independent of slice size

High cutting quality

• Exceptionally smooth surfaces

(roughness Ra < 0.3 micron)

• No thermal damage preserving

the diamond’s structural integrity

• Faster processing speed, significantly boosting throughput

Trusted by Industry Leaders

Jörg Pausch

(Business Unit Manager Diamond)

Meet our Business Unit Expert

Our business expert is here to support you every step of the way, whether you’re considering an application test, exploring our job shop services, or looking to discuss your upcoming production needs.