Medical

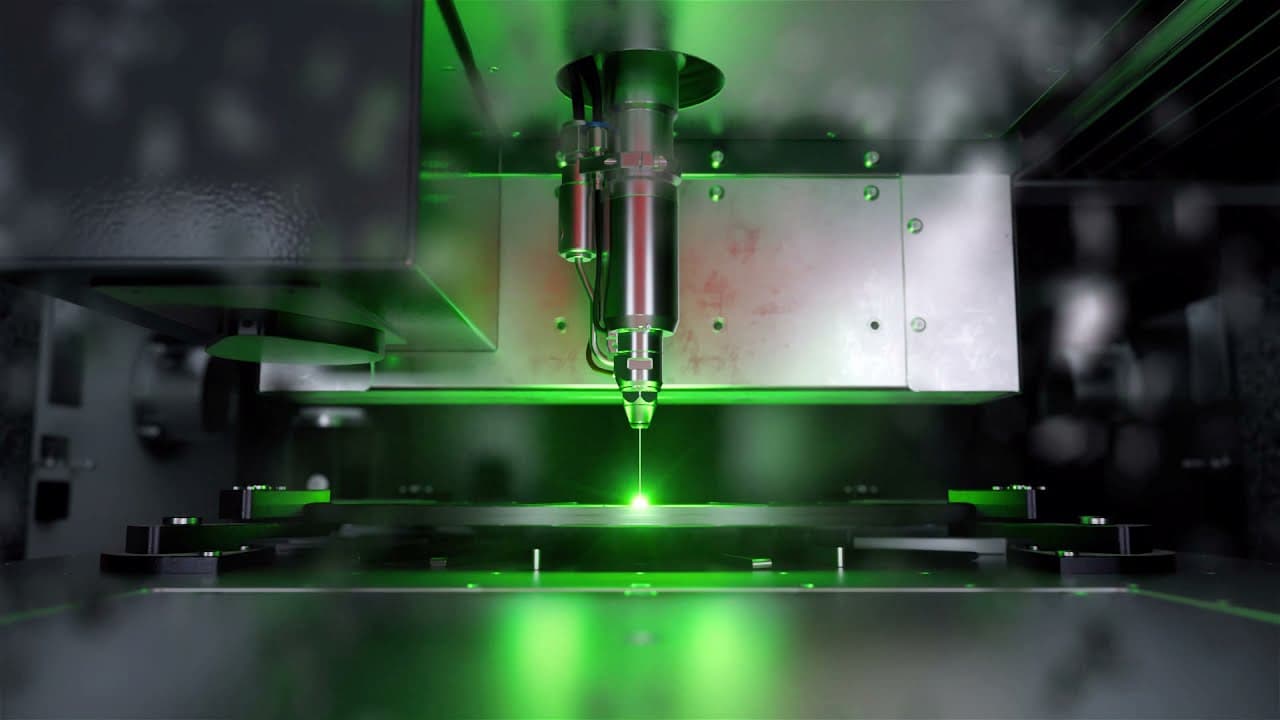

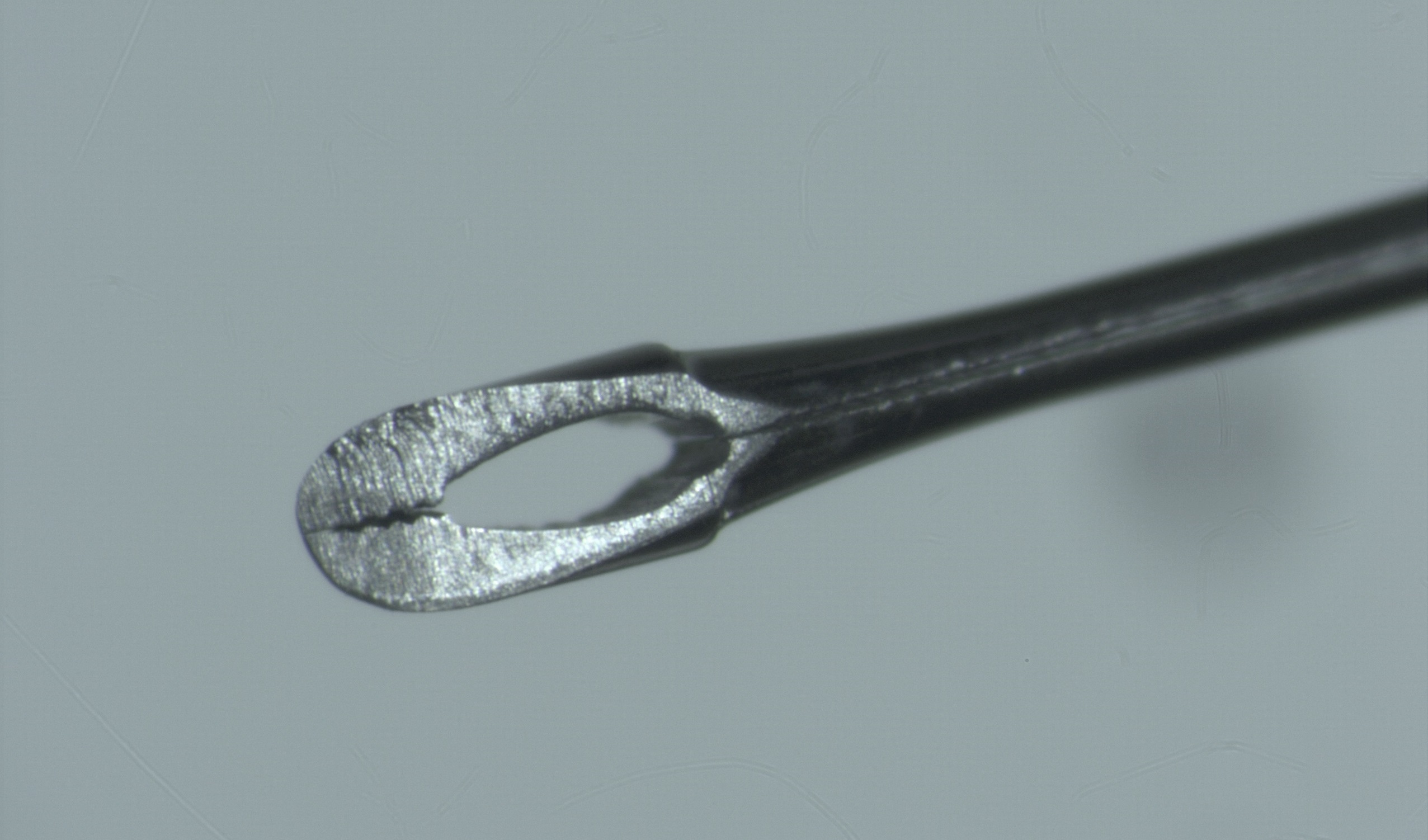

Medical devices demand the highest standards in quality, precision, and cleanliness. Synova’s Laser MicroJet® technology meets these requirements by combining the accuracy of a laser with the cooling and guiding capabilities of a thin water jet. This unique process enables clean, burr-free cutting without heat-affected zones, material deposition, or micro-cracks.

In the medical industry, the LMJ is widely used for manufacturing components such as implants, surgical blades, stents, tubes (i.e. cannulas, needles, or endoscopes), and electronic parts for implants.

Whether cutting, drilling, slotting, grooving, marking, or slicing, the Laser MicroJet delivers precision and reliability. With Synova’s technology, manufacturers benefit from a solution that meets the strict performance and regulatory demands of the medical sector.

We are also very satisfied with the wide variety of demanding materials we can process with this installation, including nitinol, titanium, tantalum, niobium, and tungsten. One of the most important advantage is the white cut, means strictly no contamination.

Norbert Giraud, CEO Microweld, Acrotec Group

Materials

Our laser MicroJet technology offers great results for the machining of a wide range of materials, whether conductive or not. It is particularly well suited for the processing of ultra-hard materials, such as super alloys, or of complex materials, such as CMCs.

Metals and alloys

Stainless steel, aluminium, Durnico, Phynox, CuBe, copper, brass, gold, shape-memory alloys (nitinol, cobalt-chrome), titanium, nickel, superalloys

Ceramics

Zirconia (ZrO2), HTCC/LTCC, aluminium nitride (AlN), alumina (Al2O3), silicon nitride (SiN), Polycrystalline cBN (PcBN), tungsten carbide (WC)

Diamonds

CVD, PCD diamond

Application Examples

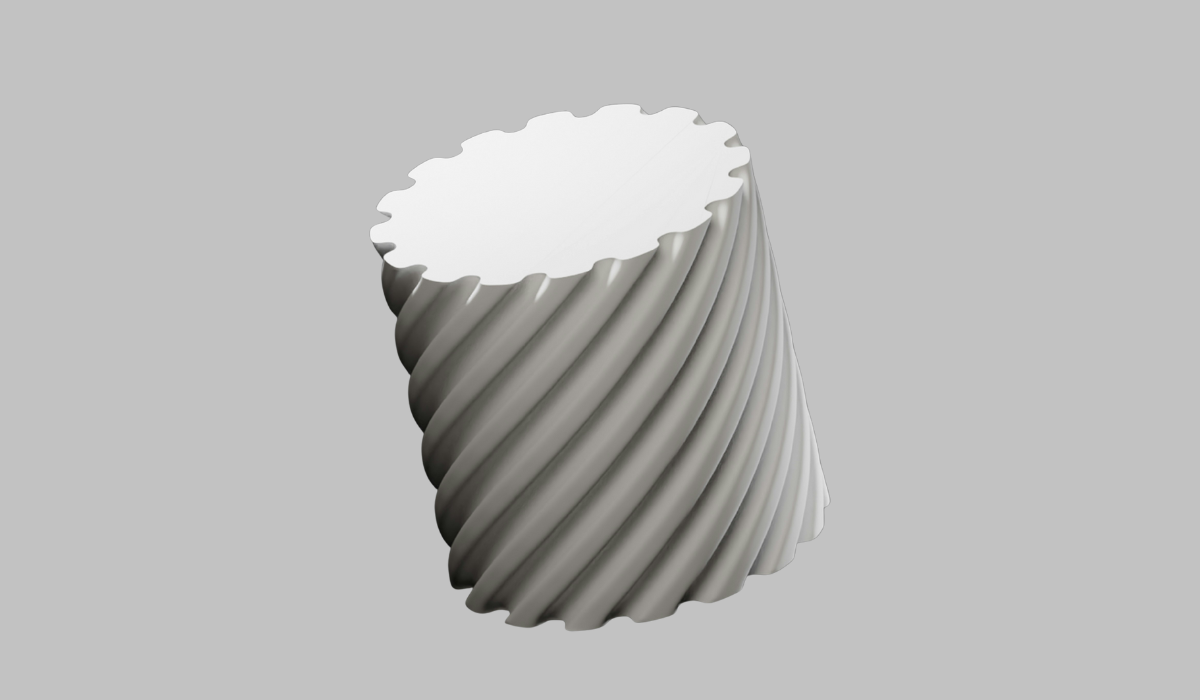

Medical tube

Nitinol

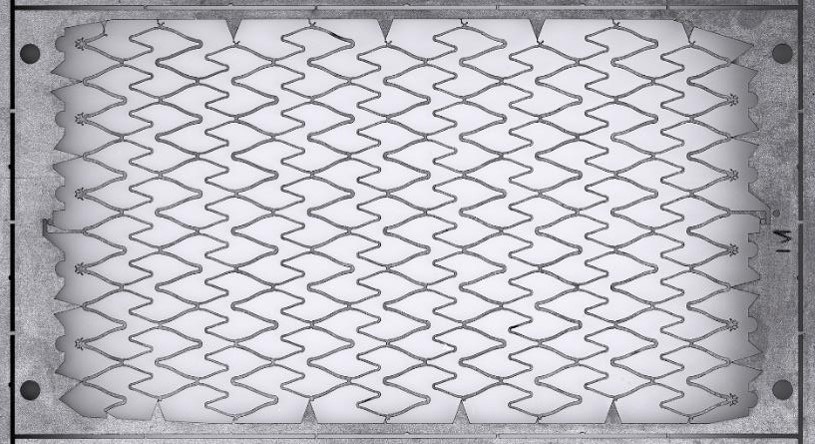

Cardiovascular flat stent

Nitinol

Surgical instrument

Phynox

Dental tool

Polycrystalline diamond

Surgical instrument

Nitinol

Case studies

Nazih Ziadé

(Business Unit Manager – Medical)

Meet our Business Unit Expert

Our business expert is here to support you every step of the way, whether you’re considering an application test, exploring our job shop services, or looking to discuss your upcoming production needs.