Others

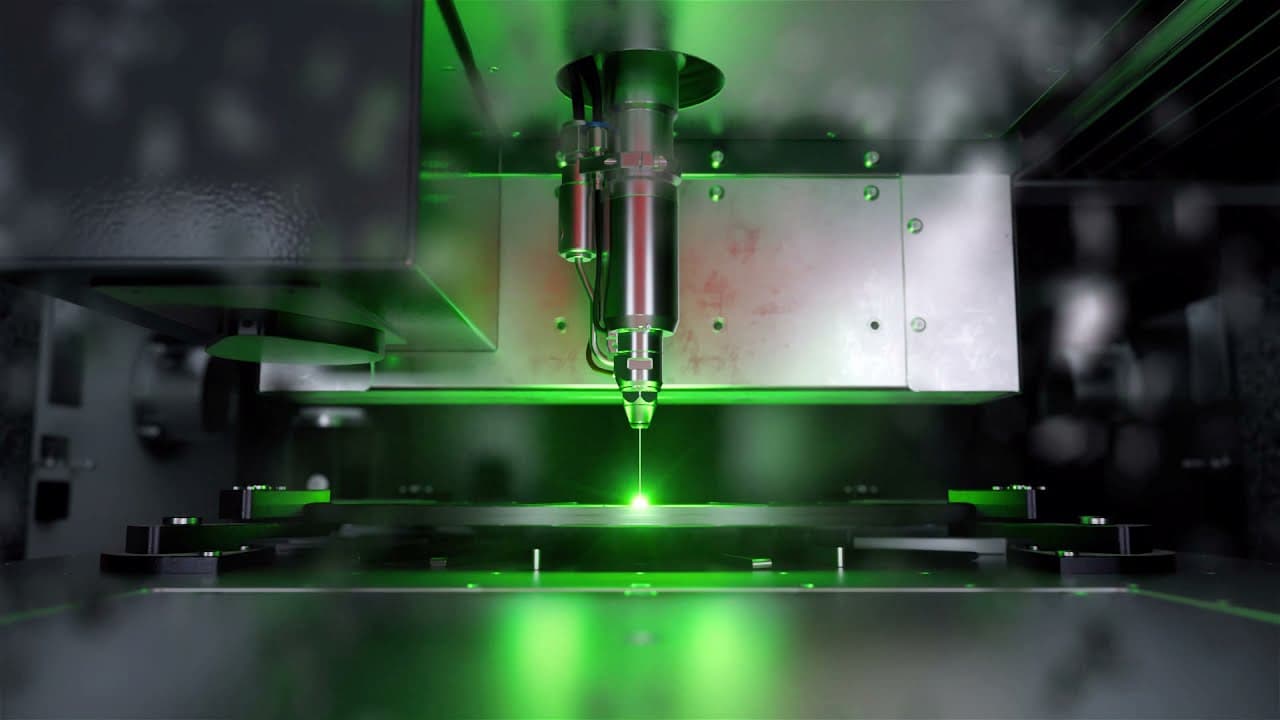

While Synova’s Laser MicroJet® technology is well-established in demanding industries such as aerospace and diamond manufacturing, its capabilities extend well beyond these sectors. From the fine precision required in watchmaking and tool manufacturing to advanced applications in automotive, defense, electronics, renewable energy, and scientific research, our systems are meeting the most complex manufacturing challenges with ease.

Each of these sectors presents unique challenges related to material processing, accuracy, and reliability. Synova’s technology helps address those challenges by providing high-quality cuts with minimal mechanical stress, thermal impact, or chipping. The water jet guidance ensures clean and precise cutting, while also preventing contamination and burr formation, particularly on the backside of components. This reduces the need for post-processing, improves part quality, and increases overall yield, making it especially valuable for sensitive materials.

The Laser MicroJet (LMJ) from Synova offers exceptional laser machining capabilities. The gentle machining process allows the production of highly accurate parts without causing heat damage, deformation or other material changes.

Mr. Kido, Makino Milling Machines, Japan

Materials

Our laser MicroJet technology offers great results for the machining of a wide range of materials, whether conductive or not. It is particularly well suited for the processing of ultra-hard materials, such as super alloys, or of complex materials, such as CMCs.

Diamond materials

Natural and lab-grown diamonds (CVD, HPHT), polycrystalline diamond (PCD), single crystalline diamond (SCD)

Metals and alloys

Stainless steel, aluminium, Durnico, Phynox, CuBe, copper, brass, gold, shape-memory alloys (nitinol, cobalt-chrome), titanium, nickel, superalloys

Ceramics

Zirconia (ZrO2), HTCC/LTCC, aluminium nitride (AlN), alumina (Al2O3), silicon nitride (SiN), Polycrystalline cBN (PcBN), tungsten carbide (WC)

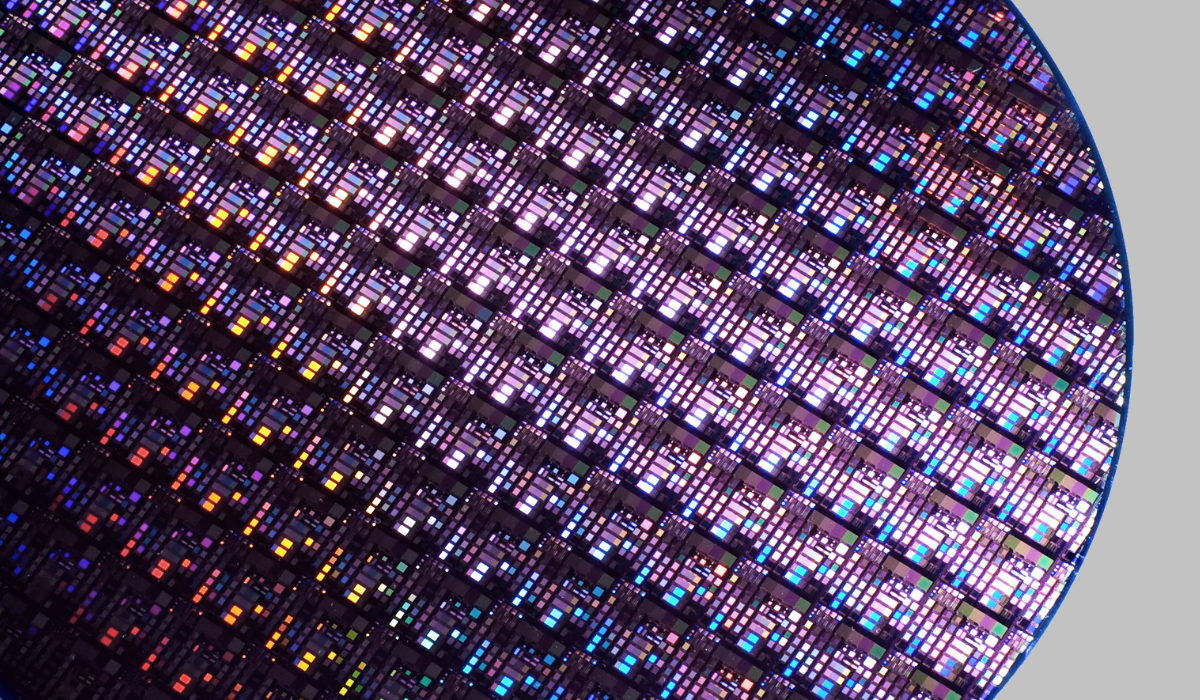

Semiconductors

Silicon (Si), gallium arsenide (GaAs), silicon carbide (SiC)

Composites

Ceramic matrix composites (CMCs), diamond-SiC/cBN composites, carbon fiber reinforced polymer (CFRP)

Main Application Examples

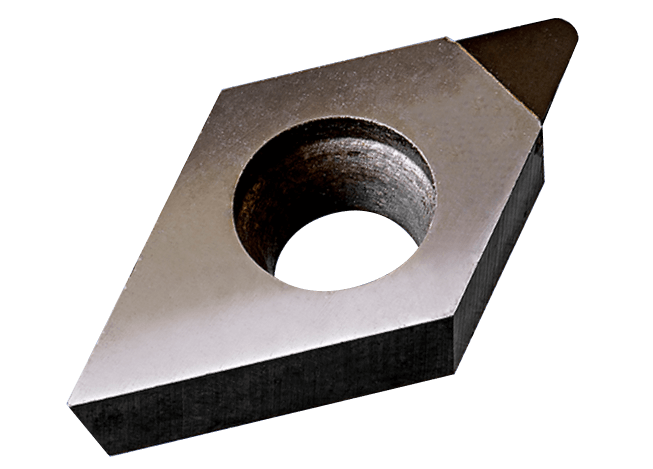

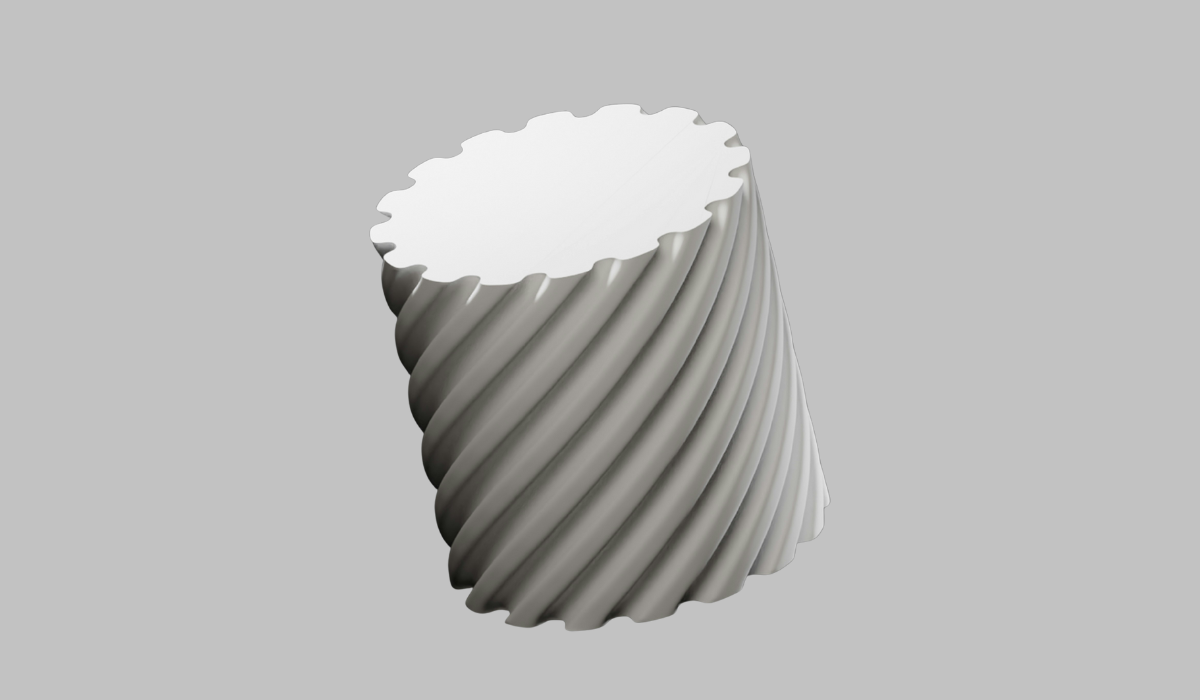

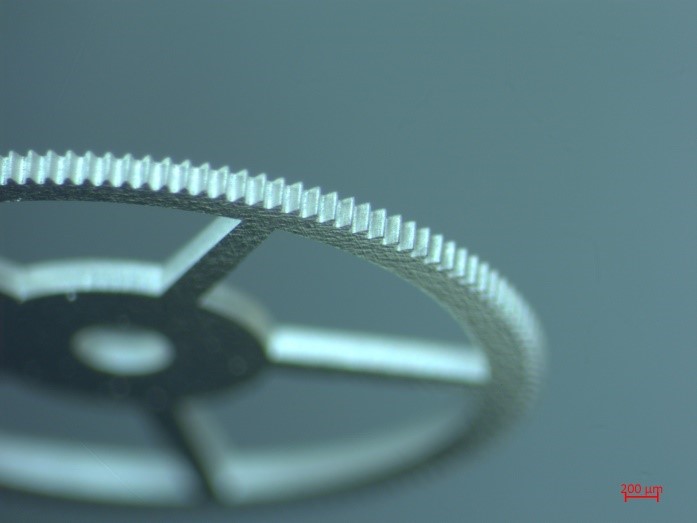

Watchmaking wheel

Phynox

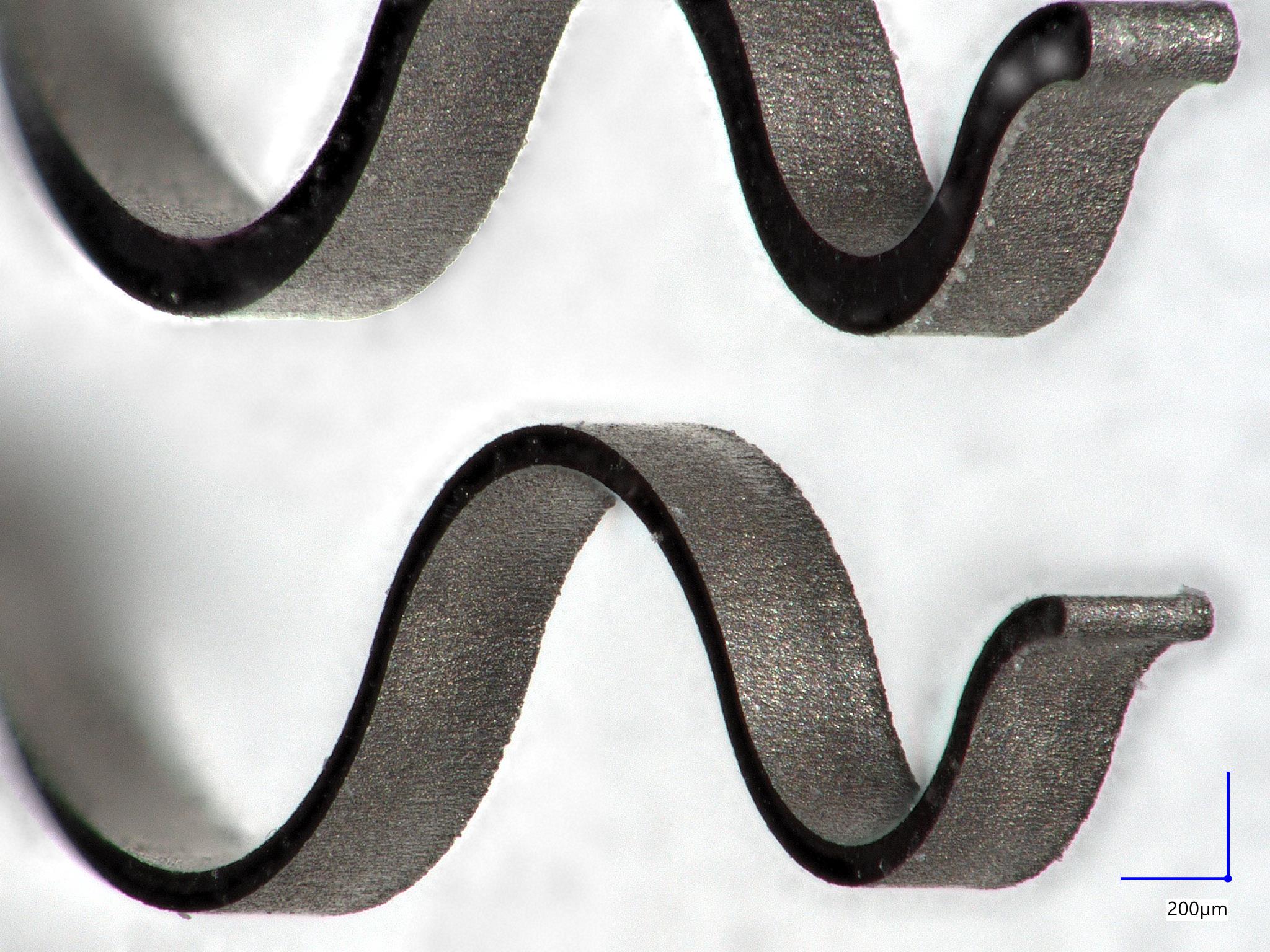

Consumer Electronics

Phynox

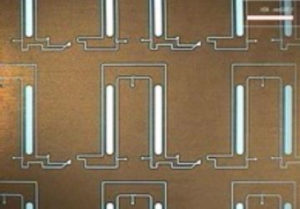

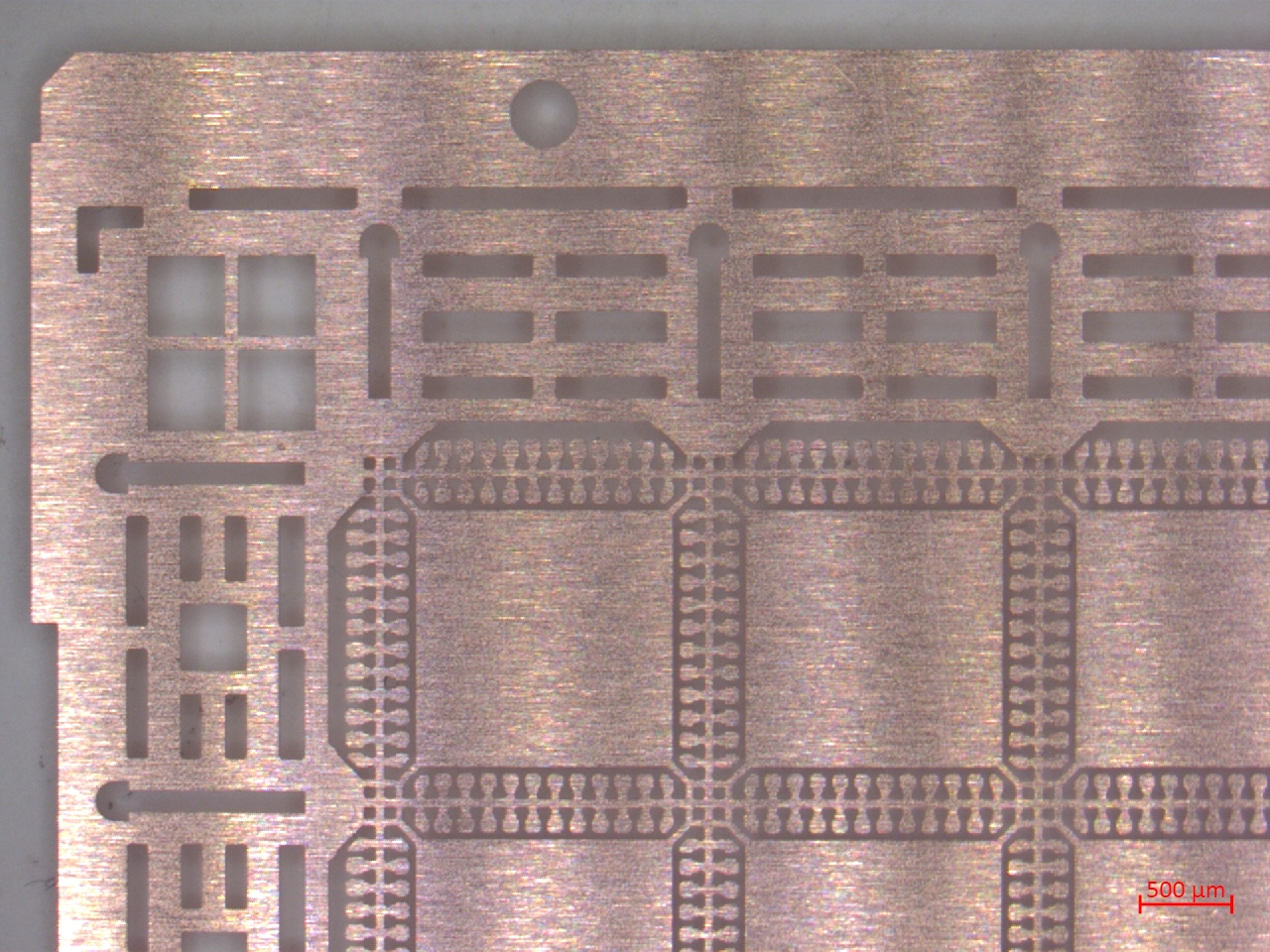

Electronics

Copper

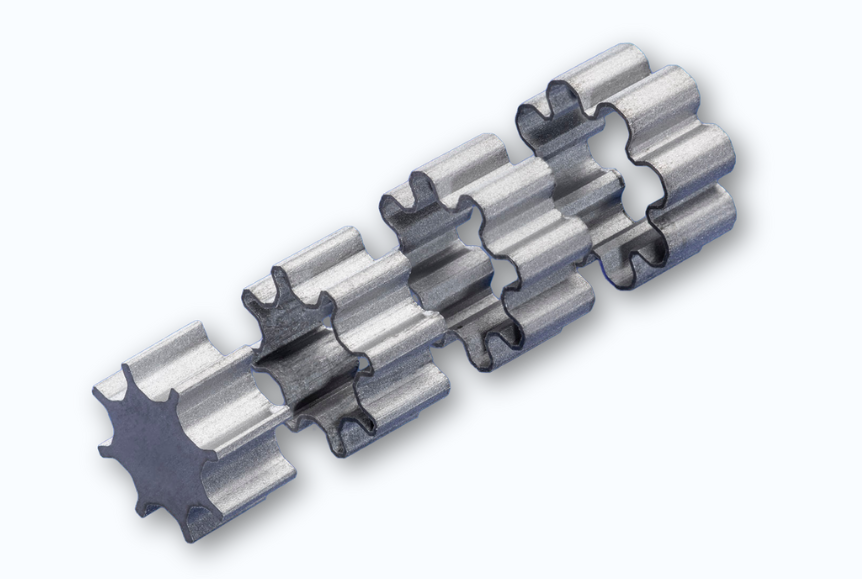

Fuel injection nozzle

Stainless steel

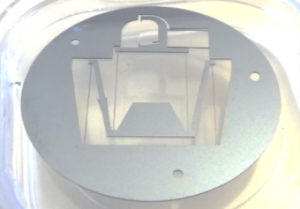

Thick ceramics

Zirconia toughened alumina

Case studies

Are you interested in a demo?

Fill out the form and we’ll get back to you as soon as possible.