The Origin Story of the Laser MicroJet®

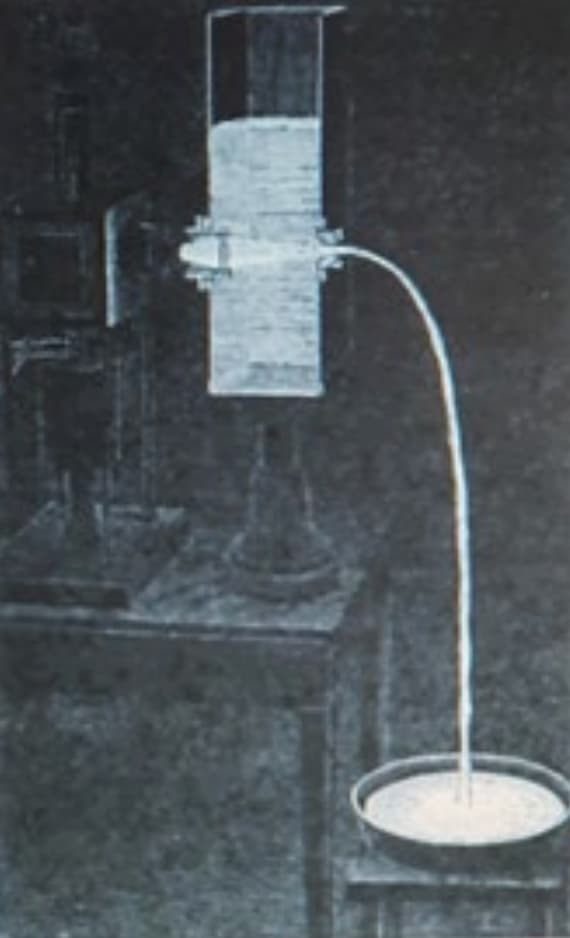

Our story begins with the fusion of water and light, which gave rise to a revolutionary manufacturing method. It all started over 180 years ago, when light was first shown to be guided by water. During an experiment at the University of Geneva, Professor Daniel Colladon demonstrated that light rays could be coupled into a laminar flow of water.

The concept was further developed in a Swiss laboratory, in 1993, when Dr Bernold Richerzhagen demonstrated its feasibility for the machining of parts.

Initially, aiming to develop a laser system for a dental tool, Richerzhagen explored an innovative approach in which the laser is guided by total internal reflection within a water jet. His approach differed fundamentally from either high-pressure water jet cutting or conventional laser machining. While the low water pressure in his process is insufficient to cut through metal, the laser provided the necessary energy to melt and vaporize it. At the same time, the water jet offered continuous cooling, minimizing heat-related damage to the material.

At that point of time, there was neither a working solution nor a commercial product of a water jet guided laser. Thus, Richerzhagen was breaking new ground.

Colladon’s water fountain with light coupled into and guided by the laminar flow of water

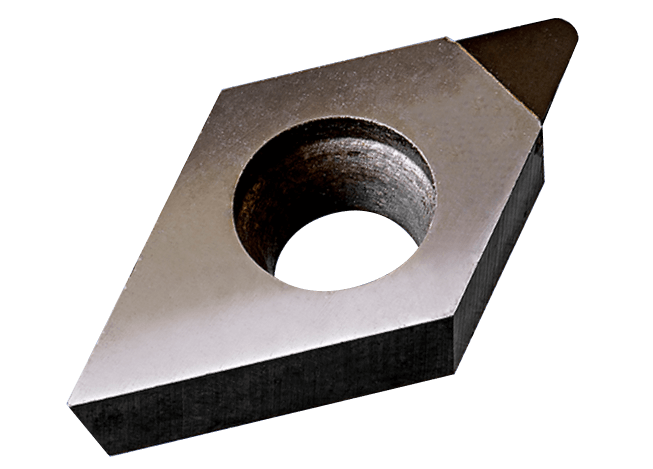

Coupling unit model

Who would have thought that combining light and water could lead to a breakthrough in precision machining? In 1993, we proved it was possible. Innovation doesn’t always come from inventing something entirely new, it often comes from reimagining what already exists.

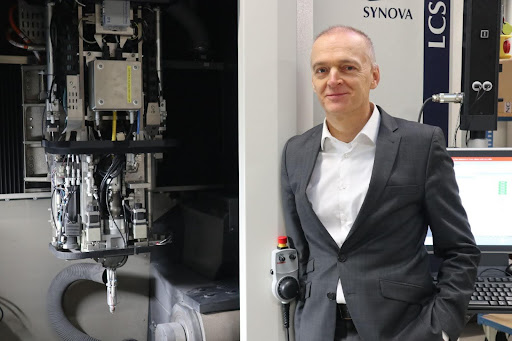

Bernold Richerzhagen

Richerzhagen spent several years in conducting practical experiments and theoretical simulations before he succeeded in building a prototype that proved his theory. In his first laboratory model, the laser beam damaged components. Eventually he established the cause. Heat from laser pulses was increasing water temperature and changing its refractive index. This, in turn, disturbed total internal reflection of the beam. He carried out intensive research to obtain accurate data on the relationship between water temperature and change in its refractive index. These results were published in prestigious journals.

Based on his findings, he designed a modified prototype that consisted of a disc-type water chamber with a highly dynamic flow, just contrary to what literature recommended. By controlling the flow, it was possible to avoid any turbulences even with a very short chamber needed to avoid the thermal effects. He successfully combined a laser with a low-pressure hair-thin water jet. There was total internal reflection of the laser beam within the water jet in a manner like a conventional optical fibre. A notable scientific achievement, he was the first man in history to do so. He patented his invention in 1994 and this technology is now marketed under the trademark: Laser MicroJet® (LMJ).

Machine 001

Bernold Richerzhagen next to the LCS 305 designed to machine milling cutters and turbine blades

Are you interested in a demo?

Fill out the form and we’ll get back to you as soon as possible.