Watch the 3D video and see how the first automated full-faceting laser system for diamonds works.

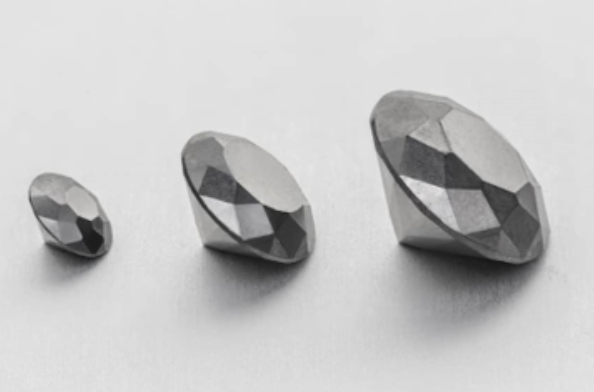

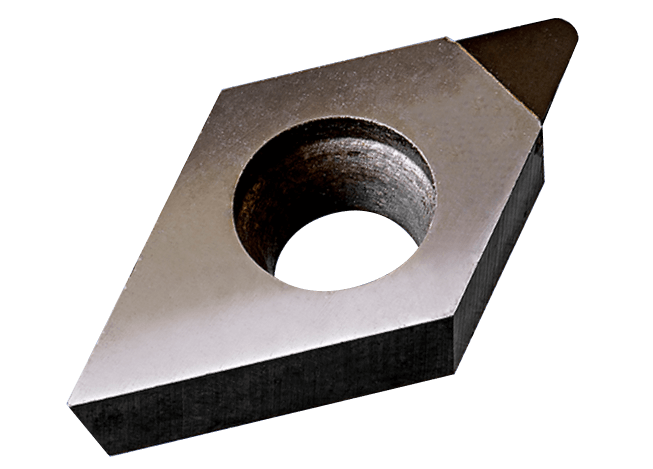

DaVinci substantially decreases diamond production time by combining several manufacturing workflows into one machine. The system covers virtually the complete rough-to-polished process. It reduces polishing processes to a final smoothing step. Several cost, skill and labor-intensive steps in the polishing phase such as crown and pavilion blocking, girdle bruting or recurrent quality checks become redundant.

As a result, manufacturing capacities can be increased or flexibly adapted according to seasonal demand and location. Customers gain a higher and more predictable polished yield through greater accuracies and improved stone symmetries. Unlike when polishing, customers also see additional value by reusing diamond chips that are cut off from rough stones during laser cutting.

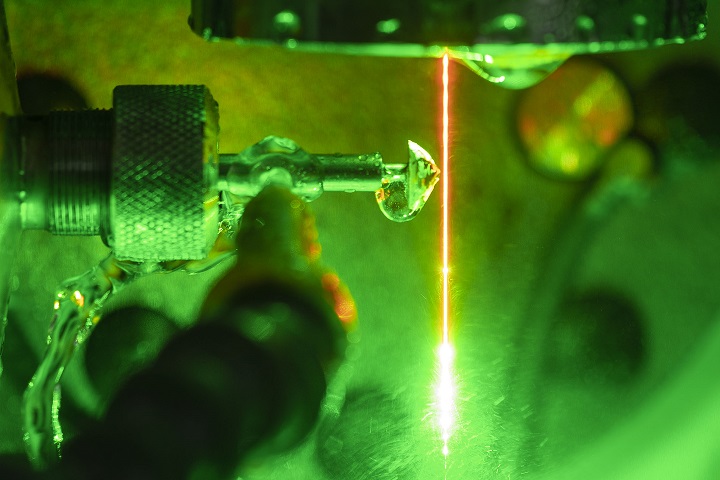

The heart of the DaVinci system is Synova’s DCS 50, a highly accurate and well-established laser machine based on the advanced Laser MicroJet® technology. The 5-axis CNC machine integrates Synova’s patented breakthrough detection that recognizes when a cut is finished and automatically initiates facet changing.

The water jet guided Laser MicroJet cools the diamond surface during laser ablation and significantly reduces the risk of rough diamond cracking, especially with stress stones. The water jet maintains the laser’s focus creating a cylindrical laser beam resulting in perfectly parallel walls and tight kerf widths.