Since no focal adjustment is required, a working distance and cutting depth of up to 30 millimeters is possible. Thus, a diamond can be cut in a single setting rather than from both sides, as it is the case with conventional lasers.

DCS 300

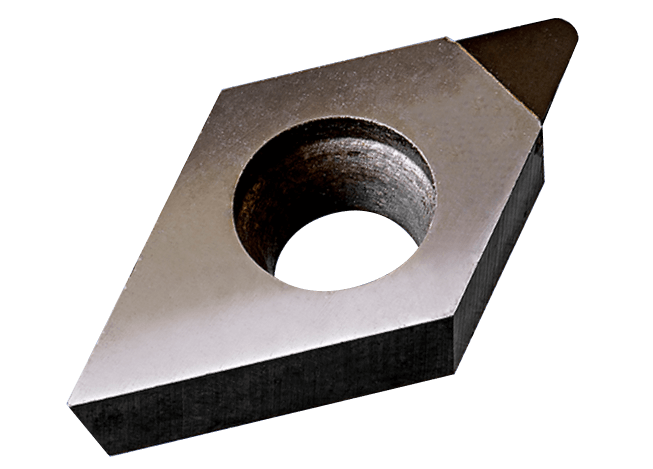

Materials

Diamond materials: Rough diamonds,Laboratory grown diamonds (CVD, HPHT)

Operations

Key Benefits

Typical Application Examples

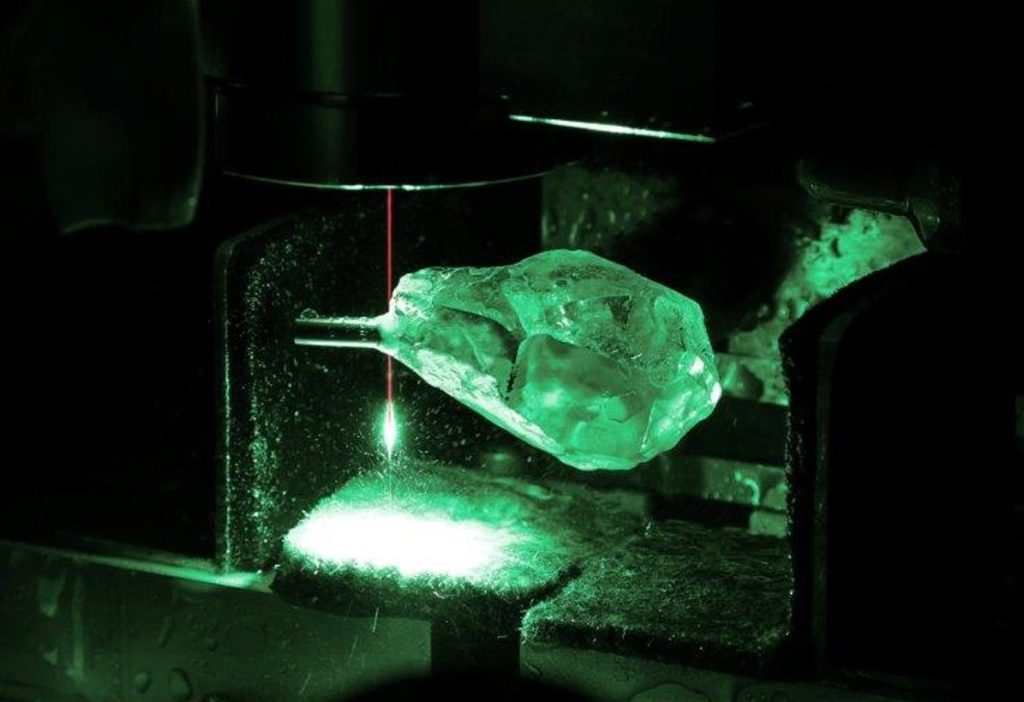

Diamond sawing

200 cts stone

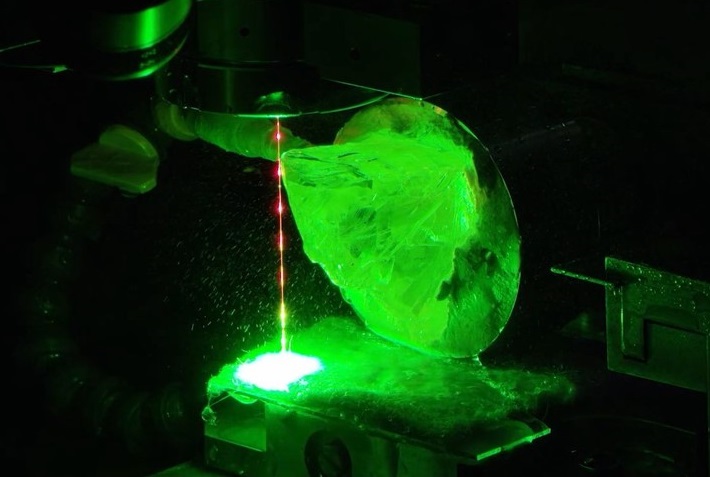

Diamond sawing

813 cts stone

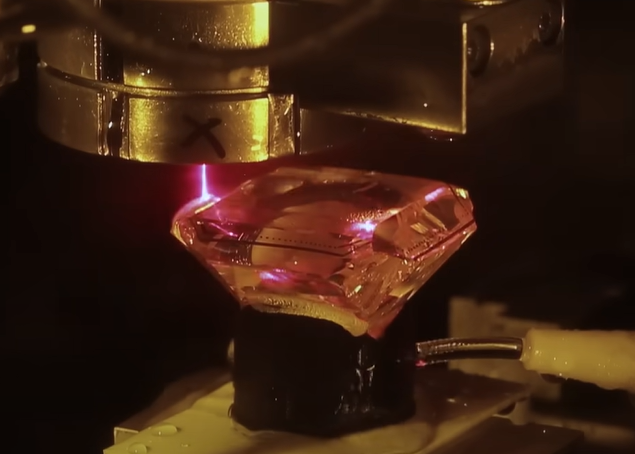

Pie cutting

12.35 cts stone

Pie cutting

4 cts stone

Bruting

302 cts stone

General Specifications

Are you interested in a demo?

Fill out the form and we’ll get back to you as soon as possible.