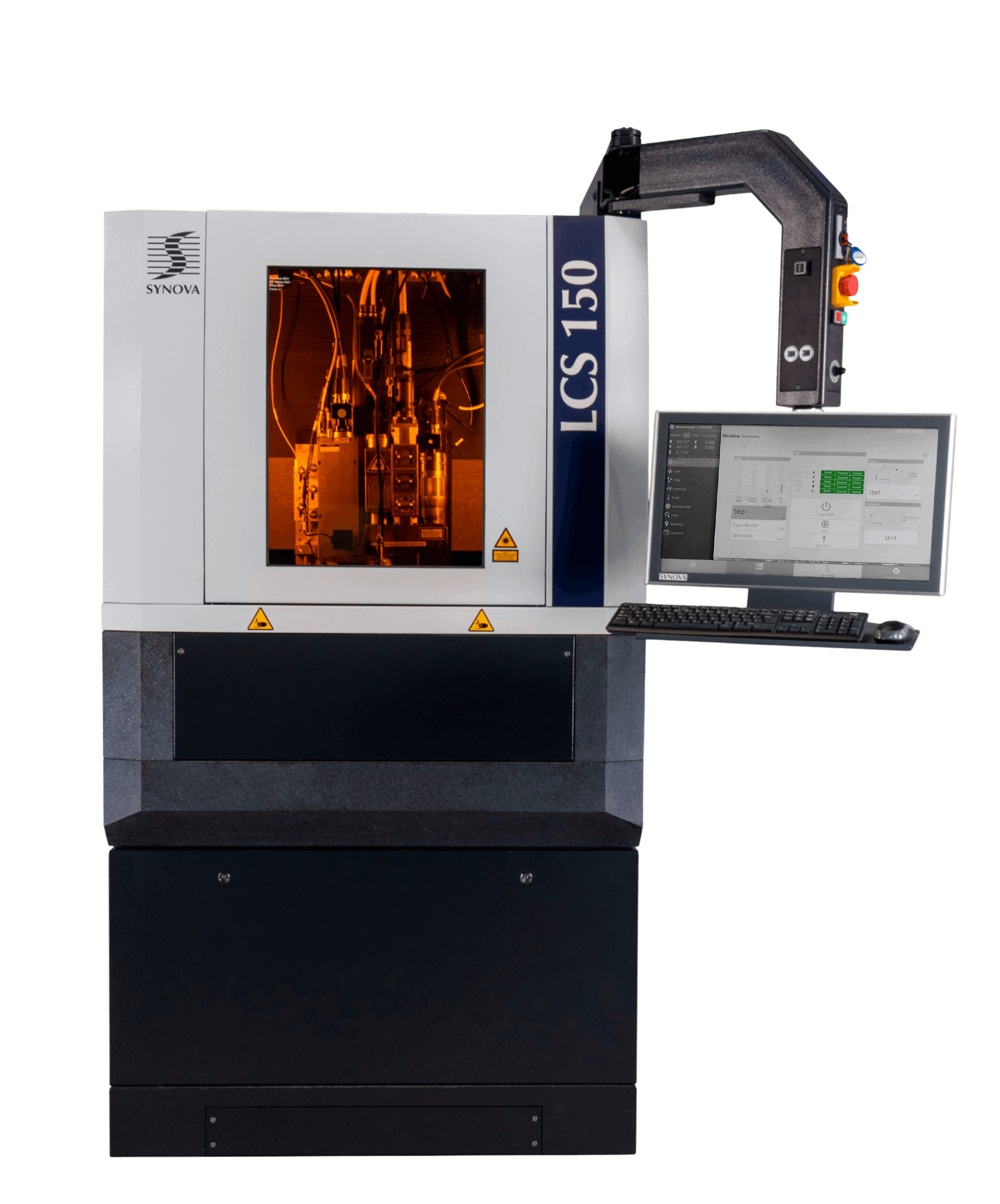

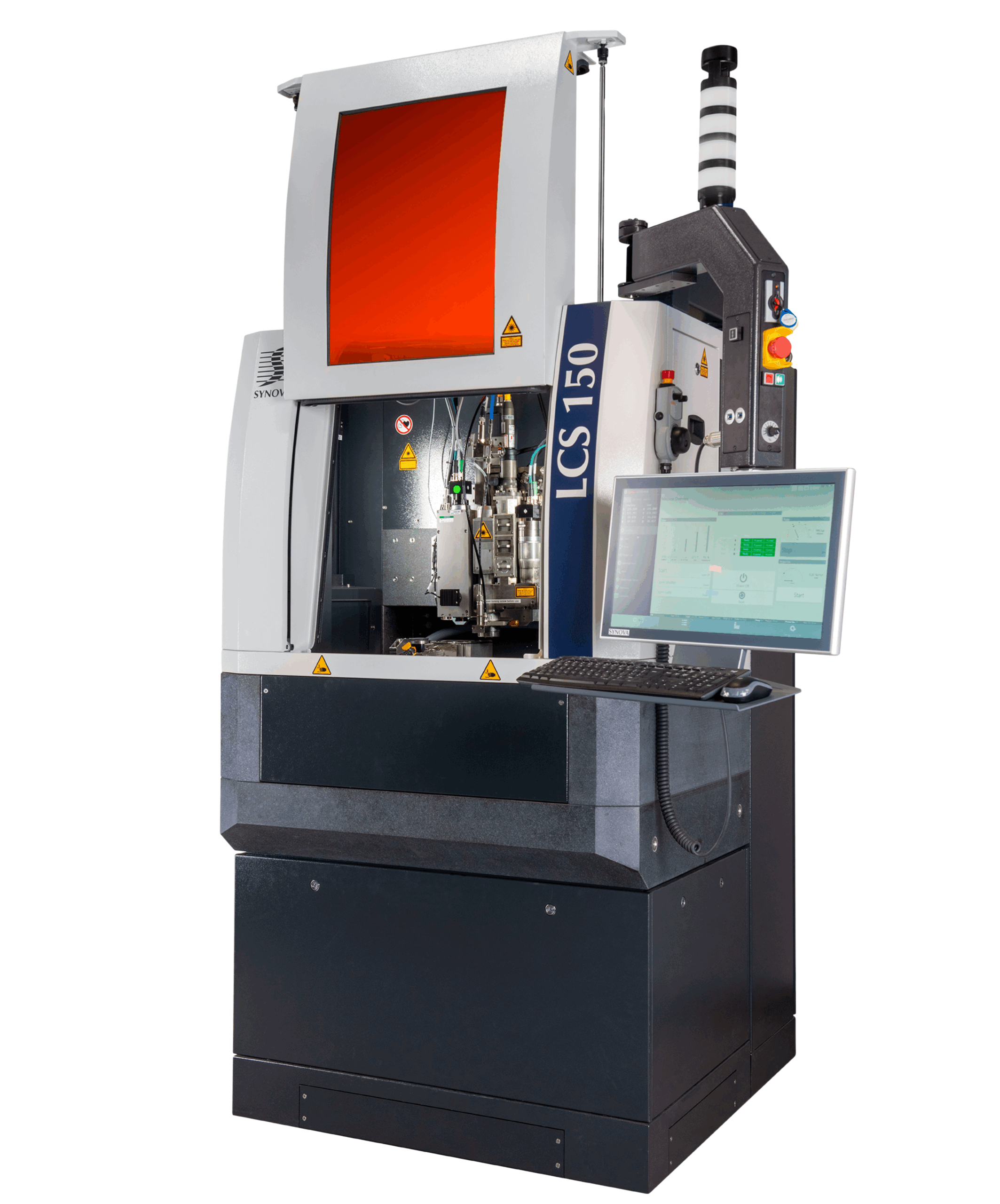

The machine uses linear X- and Y-motor axes in a cross table and the work piece is fixed on a M6-thread table. An optional B rotary axis can be mounted on the table allowing positioning the work piece with a different rotation angle.

The state-of-the-art CNC machine system includes a high-power green laser, a compact high-pressure water pump with an ultra-pure water unit, a touch-screen control panel and a vision system with motorized zoom.