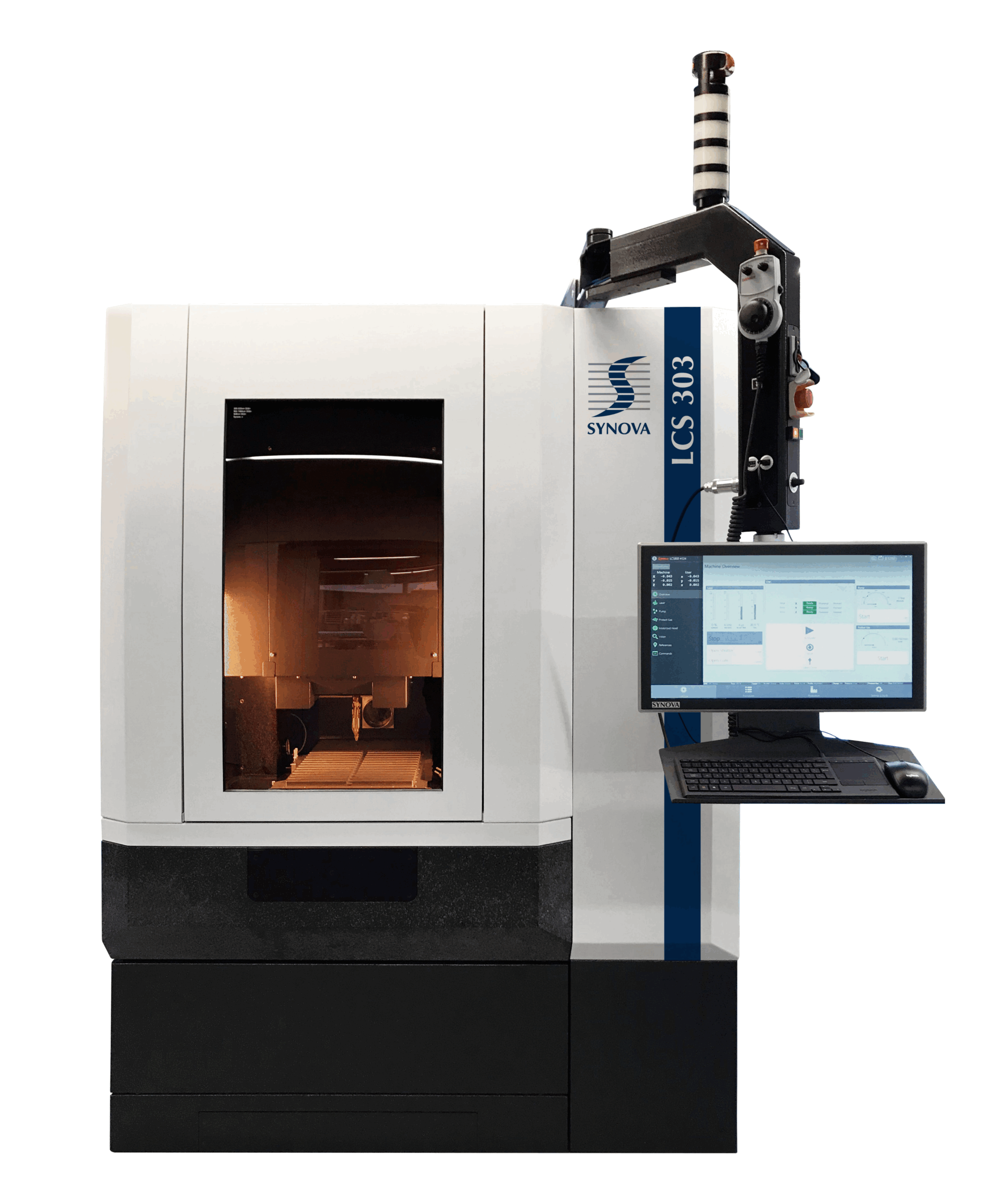

The machine with a working area of 300 x 300 mm uses linear motor axes. The work piece is fixed on a T-Nut table. An optional B rotary axis can be mounted on the table allowing to position the work piece with a different rotation angle.

The state-of-the-art CNC machine system includes a high-power green laser, a compact high-pressure water pump with an ultra-pure water unit, a touch-screen control panel and a vision system with motorized zoom.

The automated offset calibration system integrates laser-nozzle alignment, jet angle correction, laser power measurement and jet stability control (all optional).