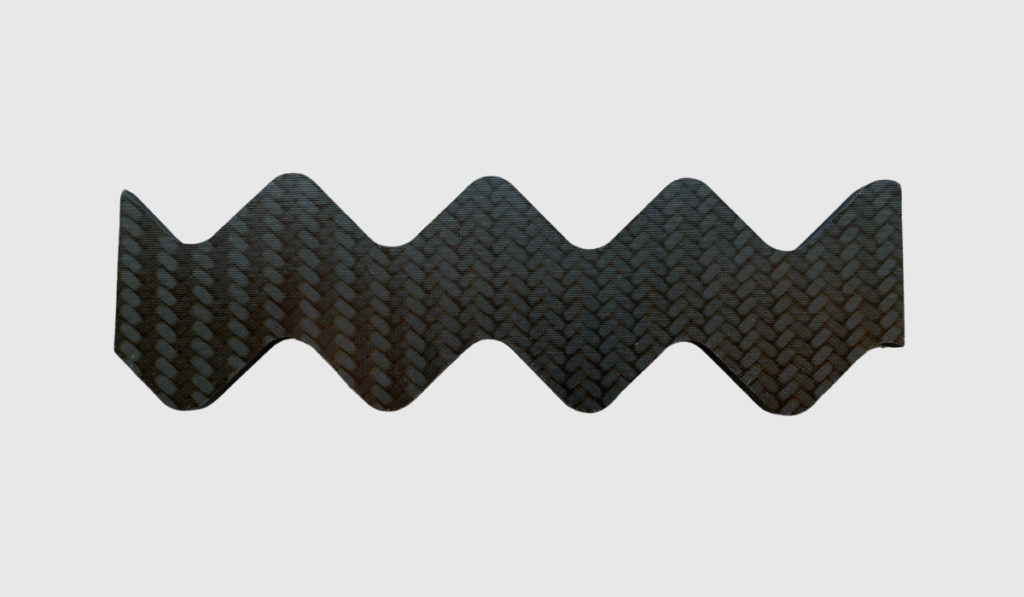

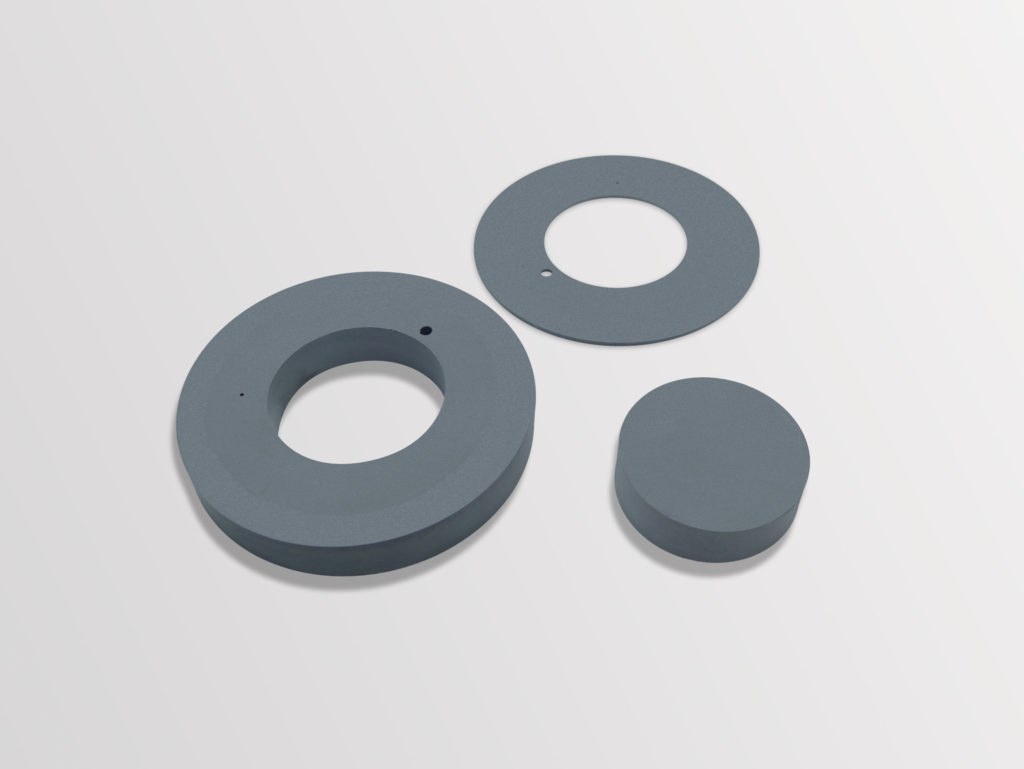

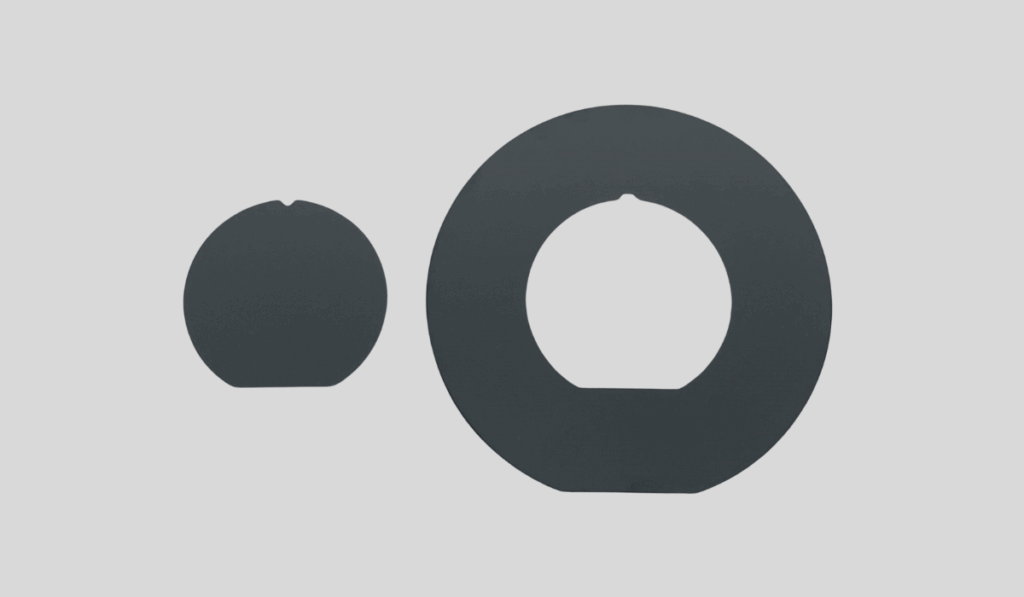

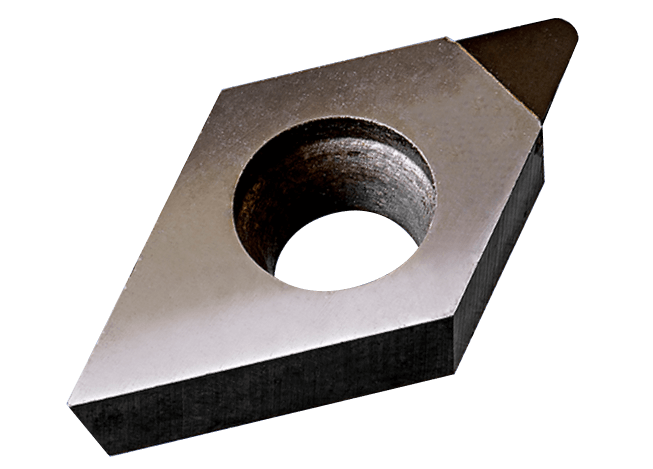

Main applications include machining of semiconductor equipment sub-assemblies, metal masks and other components made of metal, ceramics or composites (e.g. silicon carbide, CFRP).

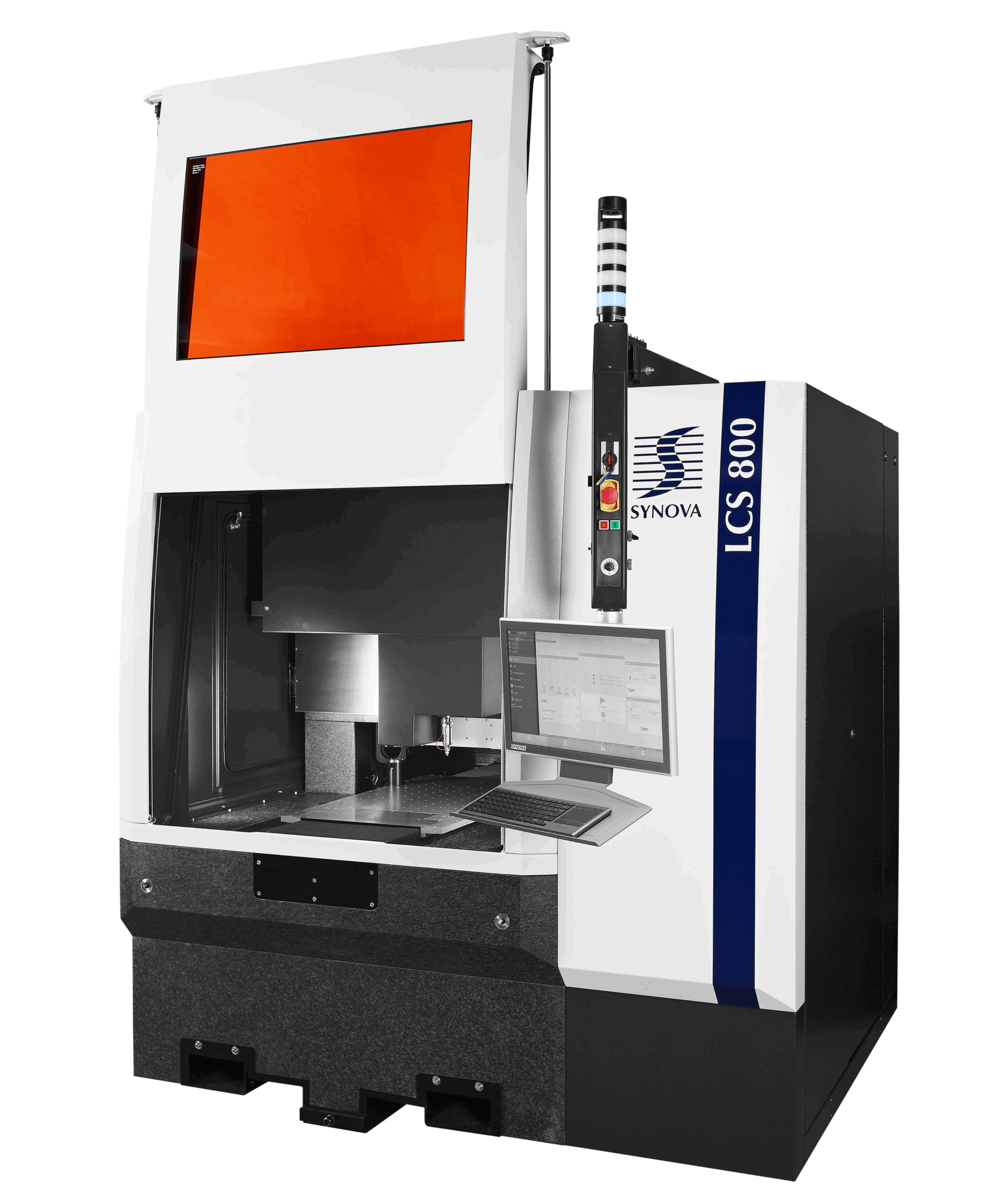

The LCS 800 has an intuitive and fully integrated system control interface with touchscreen functionality. The offset calibration system integrates automatic laser-nozzle alignment, automatic jet angle correction (both optional) and laser power control.