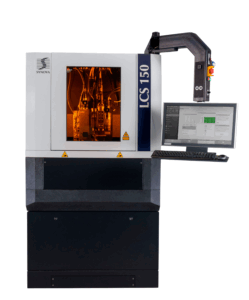

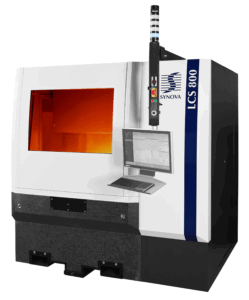

Product Portfolio

Laser MicroJet® Systems

Synova’s state-of-the-art laser cutting machines are available with a wide range of options and process automation systems. All our high-precision cutting systems feature our proprietary Laser MicroJet® technology, offering fast and accurate cutting on a wide range of materials.

Are you interested in a demo?

Fill out the form and we’ll get back to you as soon as possible.