The Unique Strenghts of the Laser MicroJet®

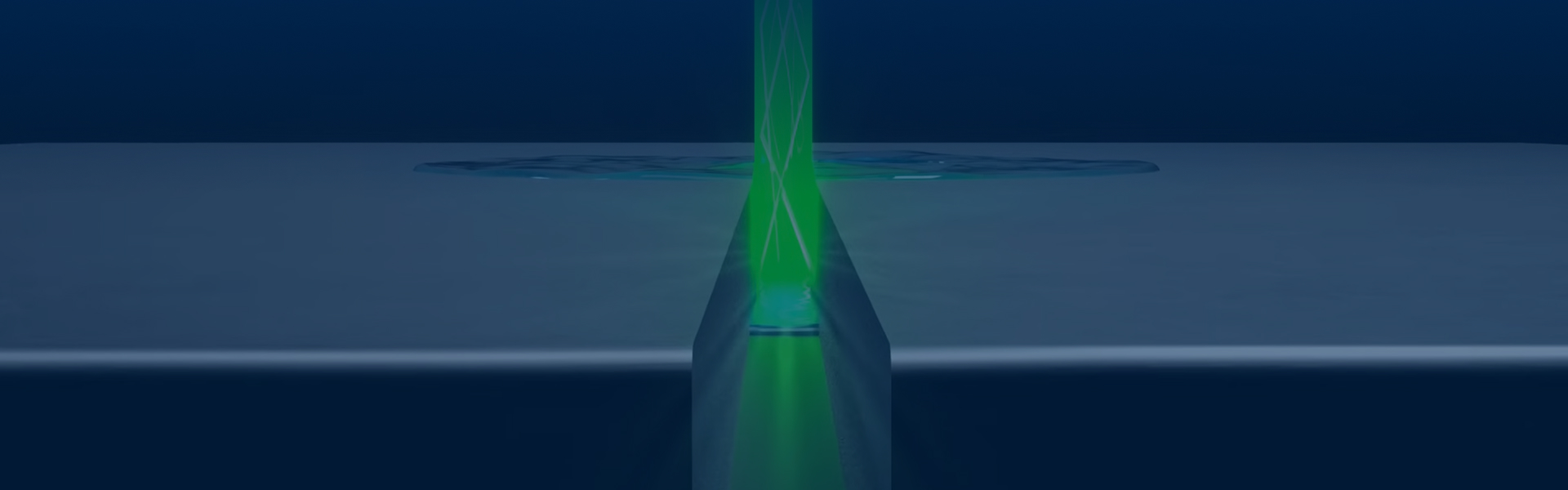

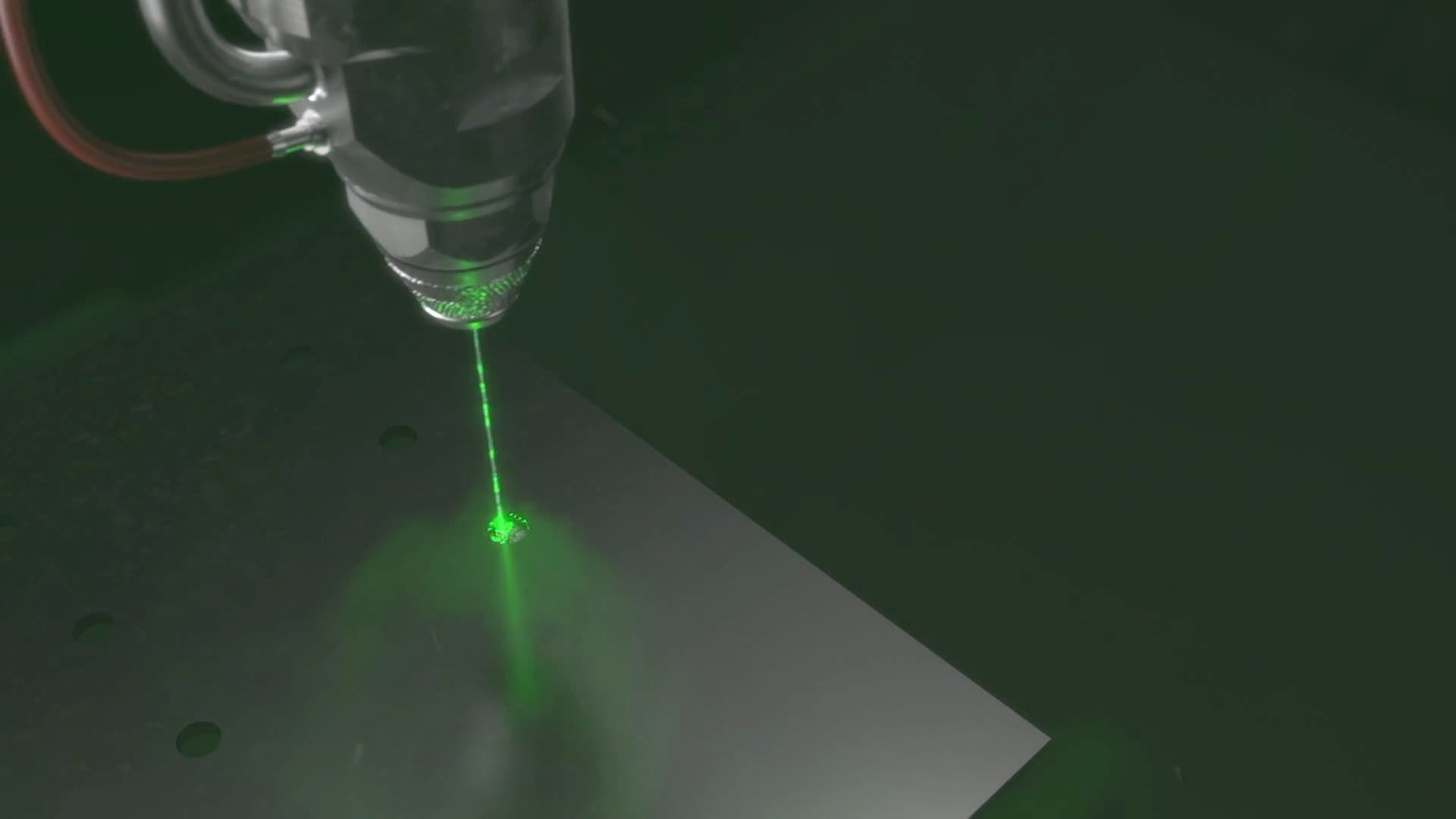

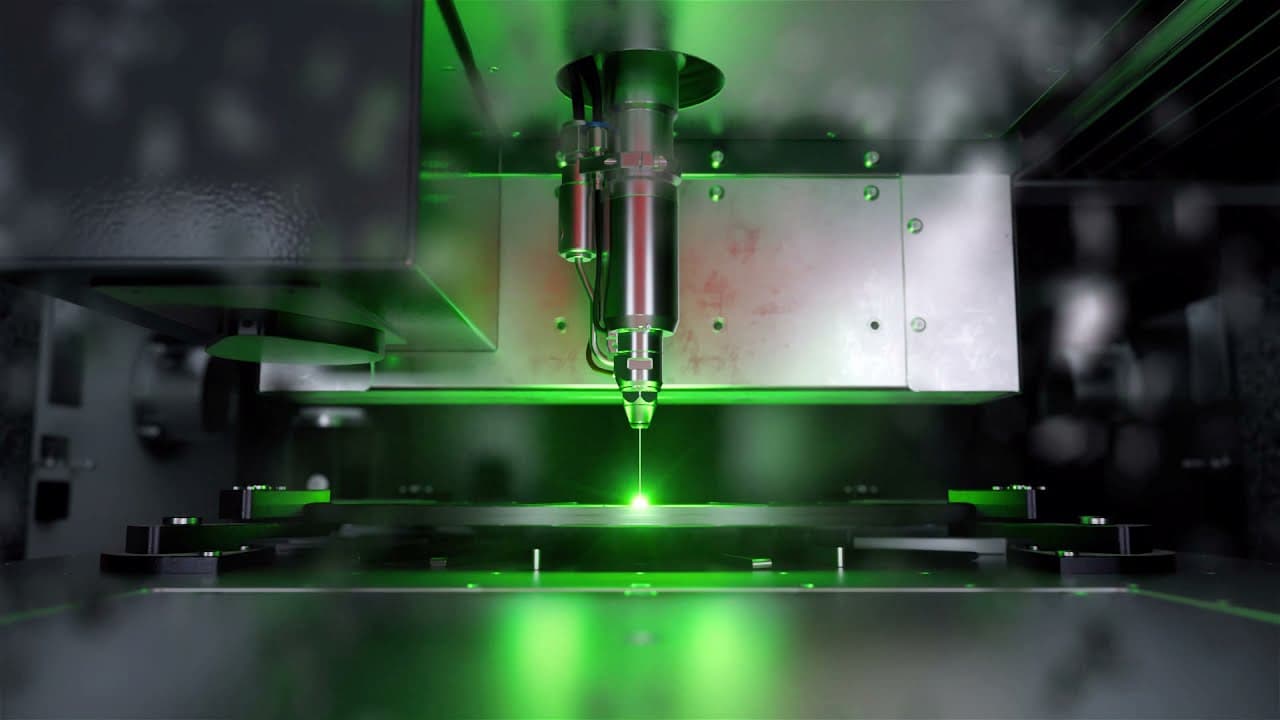

A unique cylindrical laser beam

Very small kerf width (down to 30 µm)

Parallel cut and vertical walls (no taper)

No focusing or distance control required

Less material damages due to water cooling

Low heat impact (no HAZ)

No material change

High fracture strength

No particle depositions or contamination

High accuracy and quality

High mechanical µm precision

High quality edges

Low roughness

No micro-cracks

Smooth surface

Efficiency

Fast machining

Low running costs

Low need of consumables

Minimal material loss and reduced waste

High aspect ratio

Hole-drilling with an aspect ratio up to 1:20 (diameter by depth)

Materials

Our laser MicroJet technology offers great results for the machining of a wide range of materials, whether conductive or not. It is particularly well suited for the processing of ultra-hard materials, such as super alloys, or of complex materials, such as CMCs.

Diamond materials

Natural and lab-grown diamonds (CVD, HPHT), polycrystalline diamond (PCD), single crystalline diamond (SCD)

Metals and alloys

Stainless steel, aluminium, Durnico, Phynox, CuBe, copper, brass, gold, shape-memory alloys (nitinol, cobalt-chrome), titanium, nickel, superalloys

Ceramics

Zirconia (ZrO2), HTCC/LTCC, aluminium nitride (AlN), alumina (Al2O3), silicon nitride (SiN), Polycrystalline cBN (PcBN), tungsten carbide (WC)

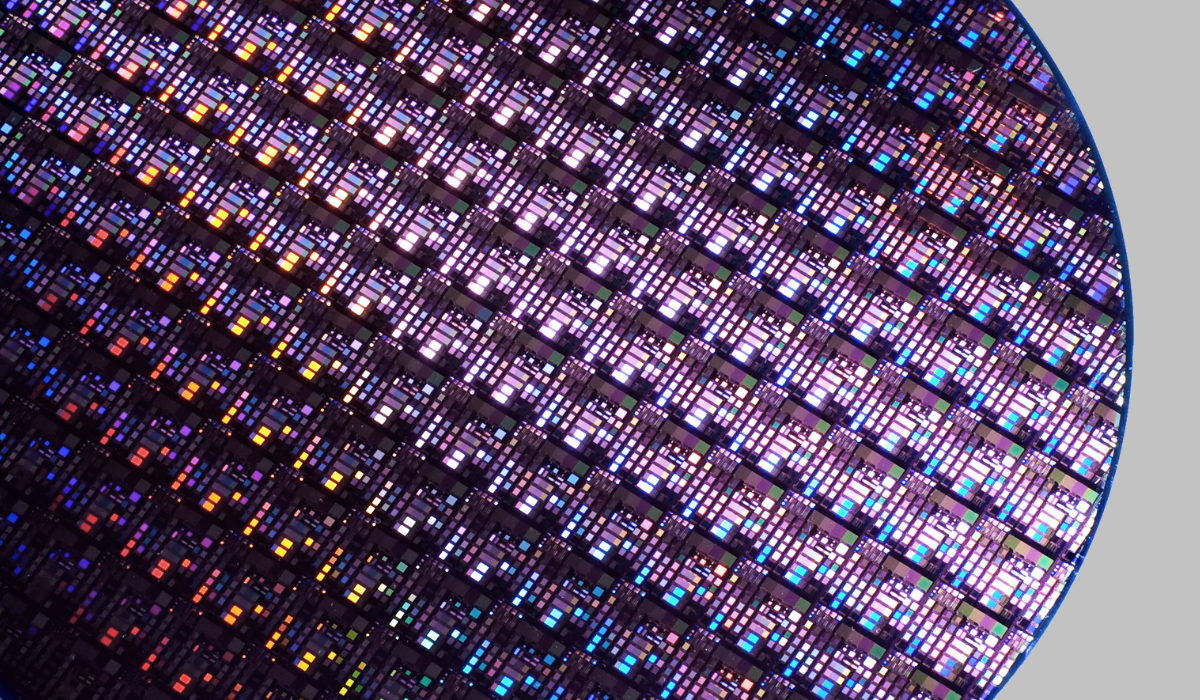

Semiconductors

Silicon (Si), gallium arsenide (GaAs), silicon carbide (SiC)

Composites

Ceramic matrix composites (CMCs), diamond-SiC/cBN composites, carbon fiber reinforced polymer (CFRP)

Operations

Synova’s product portfolio, ranging from 2 to 5 axis machines, provides perfect flexibility and enables manufacturers to find the perfect fit for their applications. In addition, thanks to it’s versatile technology, the laser MicroJet can be used for a multitude of processes while achieving unparalleled precision. Our systems can perform complex operations such as:

• Cutting

• Drilling

• Turning

• Pocketing

• Chamfering

• 3D cutting

Discover the advantages of the Laser MicroJet®

for your application

If you have any questions, fill out the form, and we’ll get back to you as soon as possible.

Download our technology brochure

Explore the power of Laser MicroJet®, get in-depth insights into our cutting-edge technology and its applications.