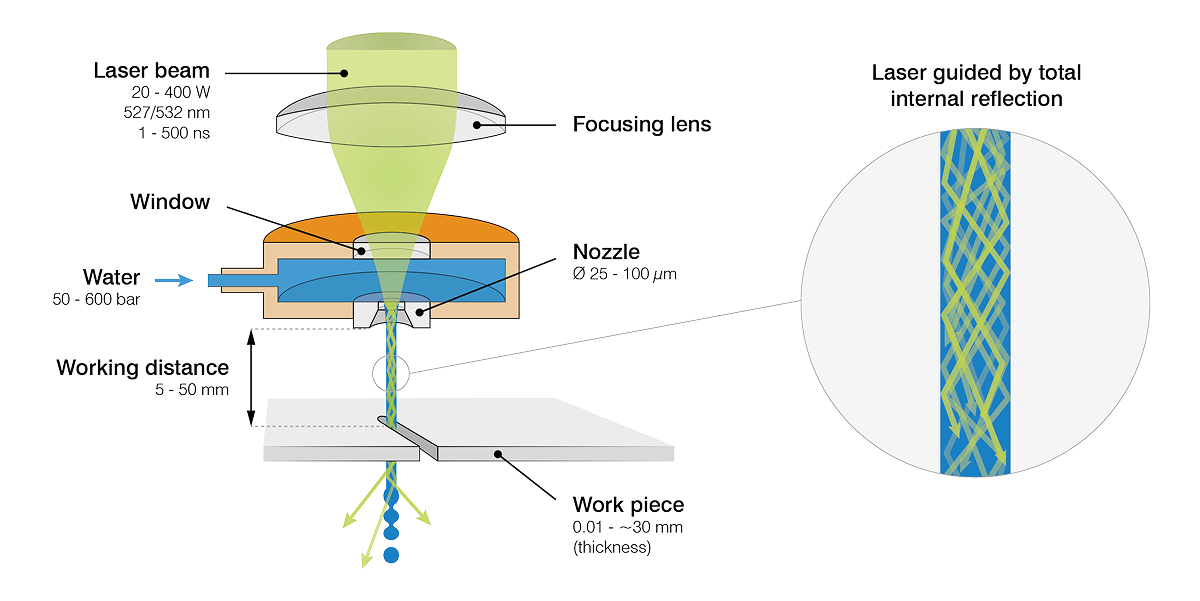

The Laser MicroJet® Technology

A Simple Principle

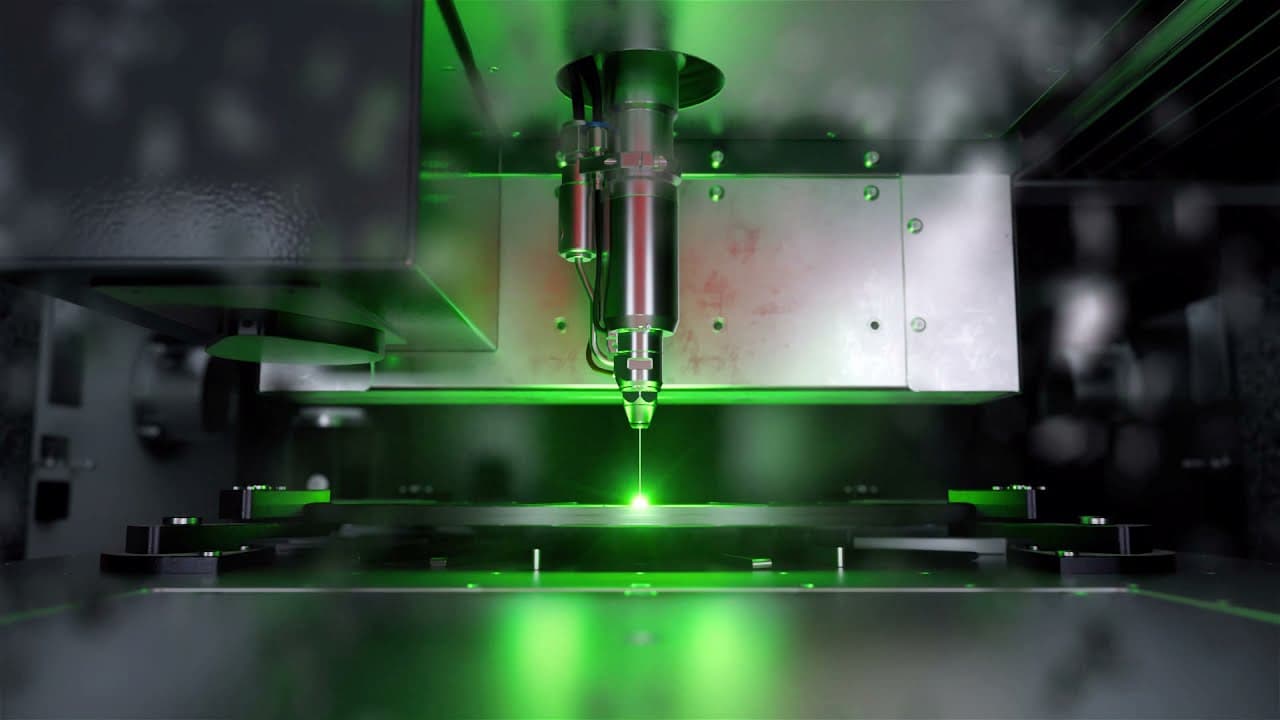

The Laser MicroJet (LMJ) is a hybrid method of machining, which combines a laser with a “hair-thin” water jet that precisely guides the laser beam by means of total internal reflection in a manner similar to conventional optical fibers. The water jet continually cools the cutting zone and efficiently removes debris.

As a “cold, clean and controlled laser”, Synova’s LMJ technology resolves the significant problems associated with dry lasers such as thermal damage, contamination, deformation, debris deposition, oxidation, micro-cracks and taper.

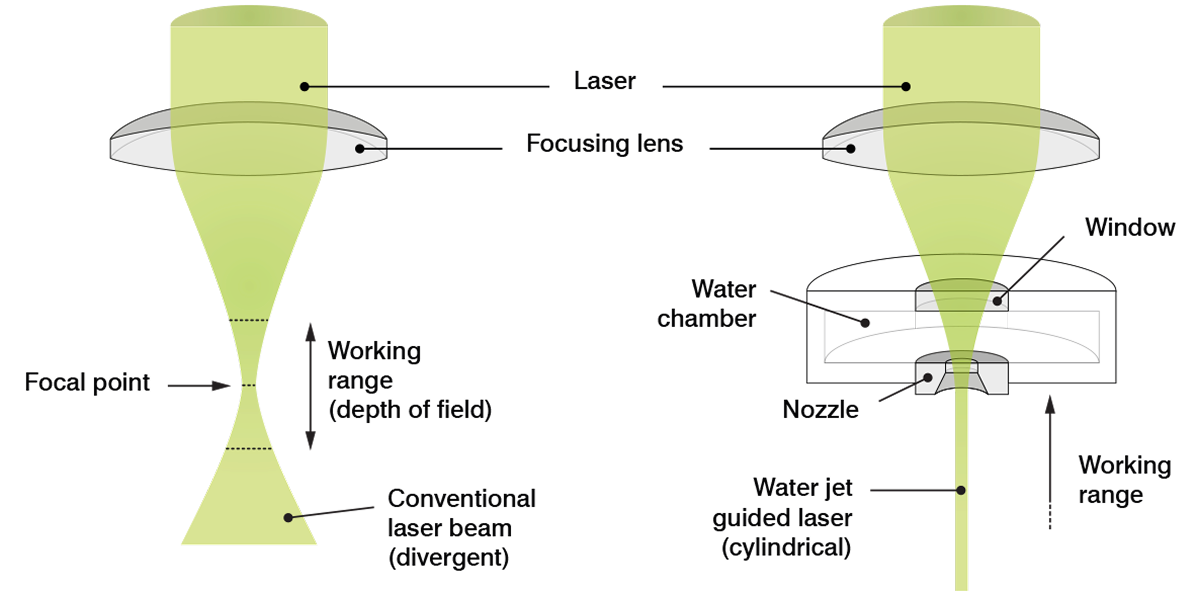

Comparison of Conventional and MicroJet Laser Beams

Conventional Laser Beam (left)

A conventional focused laser beam has a very short working distance due to beam divergence. As the beam spreads, precise focusing and strict distance control become essential to maintain cutting accuracy. This constraint also limits the achievable kerf width-to-depth ratio, making it challenging to cut deep structures with narrow kerfs efficiently.

Laser MicroJet® (right)

The Laser MicroJet® (LMJ) technology uses a laser beam that is entirely confined within a “hair-thin” water jet. Thanks to this innovative method, the laser beam remains perfectly parallel, enabling high aspect ratio kerfs. Unlike traditional laser cutting, LMJ eliminates the need for focusing or distance control, effectively overcoming the limitations caused by beam divergence.

Frequently Asked Questions

Find answers to common questions about our technology, services, and applications.

Learn more about the key advantages of our unique water jet guided laser technology

Get in touch with our team

If you have any questions, fill out the form, and we’ll get back to you as soon as possible.

Download our technology brochure

Explore the power of the Laser MicroJet®, get in-depth insights into our cutting-edge technology and its applications.